CBM for Industry 4.0 introduces students to the world of machine diagnostics and informs them on how to use state-of-the art smart sensors to monitor the conditions of machines and identify subtle defects before they become big problems. While it is an essential companion to predictive maintenance, condition-based monitoring (CBM) also concentrates on general machine health and efficiency.

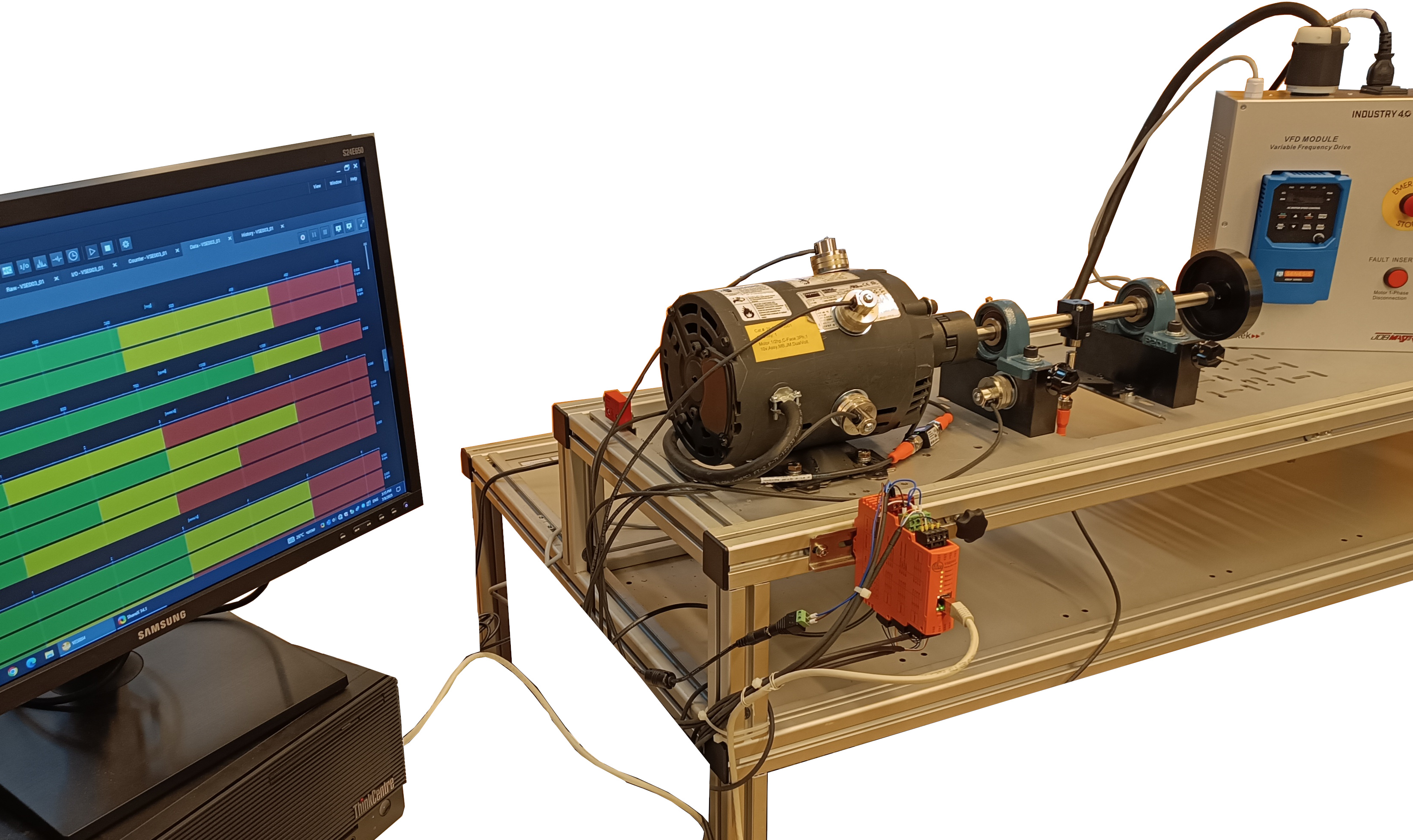

Intelitek’s JobMaster Machine, a modified variant of the JobMaster Mechanical Bench, is the focus of this course. Following guided instructions, students cause minor faults in the machine and then explore how these machine defects can be identified using sensors and monitoring software.

CBM sensor kit includes a magnetic sensor for monitoring rotational speed, a temperature sensor, and four all-important vibration sensors. The vibration sensors provide the bulk of the data used by the student-analysts, who will use the tools in the monitoring software to find machine abnormalities such as unbalance, looseness, and misalignment.

Catalog number: 88-3300-0011

Version number: 1.0.0.1