LearnMate 7.3.2 Demo Site

Course categories

Skip available courses

Available courses

Tecnología PLC con CompactLogix de Allen-Bradley es una serie de cuatro cursos enfocados en los fundamentos básicos necesarios para comprender cómo funcionan y cómo se programan los PLC. Los cursos incluyen el hardware y el software utilizados en la industria de la automatización: el Allen-Bradley CompactLogix 5380 de Rockwell y el paquete de programación de PLC Studio 5000 Logix Designer.

El primer curso de la serie hace hincapié en los fundamentos de la teoría del PLC y los conceptos esenciales de la programación de lógica de escalera. El curso concluye con una serie de proyectos de programación de PLC.

Número de Catálogo 88-8230-0010ES

Versión 1.0.0.1

- Teacher: Avery Erwin-McGuire

Tecnología PLC con CompactLogix de Allen-Bradley es una serie de cuatro cursos enfocados en los fundamentos básicos necesarios para comprender cómo funcionan y cómo se programan los PLC Los cursos incluyen el hardware y el software utilizados en la industria de la automatización: el controlador Allen-Bradley CompactLogix 5380 de Rockwell y el paquete de programación PLC Studio 5000 Logix Designer.

El segundo curso de la serie se centra en la memoria del PLC, los temporizadores, los contadores y las instrucciones de bit importantes. El curso también incluye una serie de proyectos de programación de PLC.

Número de catálogo: 88-8230-0020ES

Versión: 1.0.0.0

Tecnología PLC con CompactLogix de Allen-Bradley es una serie de cuatro cursos enfocados en los fundamentos básicos, necesarios para comprender cómo funcionan y cómo se programan los PLC. Los cursos incluyen el hardware y el software utilizados en la industria de la automatización: el controlador Allen-Bradley CompactLogix 5380 de Rockwell y el paquete de programación PLC Studio 5000 Logix Designer.

El tercer curso de esta serie se centra en las instrucciones matemáticas y de comparación en el diagrama de escalera. También se incluye una serie de proyectos de programación de PLC.

Número de catálogo: 88-8230-0030ES

Versión: 1.0.0.0

Tecnología PLC con CompactLogix de Allen-Bradley es una serie de cuatro cursos enfocados en los fundamentos básicos para comprender cómo funcionan y cómo se programan los PLC. Los cursos incluyen el hardware y el software utilizados en la industria de la automatización: El controlador Allen-Bradley CompactLogix 5380 de Rockwell y el paquete de programación PLC Studio 5000, que incluye Logix Designer (para la programación del PLC) y View Designer (para la configuración de la pantalla HMI).

El cuarto curso de la serie se centra en la comunicación PLC, la interfaz hombre-máquina (HMI) de Allen-Bradley y diversos conceptos y técnicas avanzados de programación. También se incluye una serie de proyectos de programación de PLC.

Número de catálogo: 88-8230-0040

Versión: 1.0.0.0

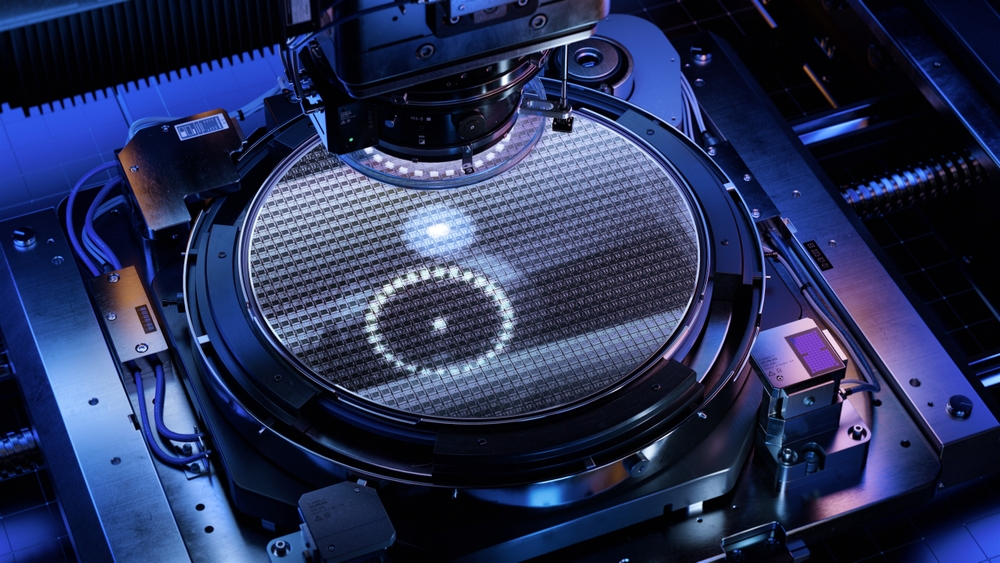

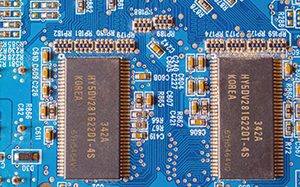

Safety for Semiconductor Manufacturing introduces high school students to the essential safety practices used in real semiconductor fabrication facilities. Students explore fab safety basics, electrical and chemical hazards, ergonomics, mechanical, vacuum, and pneumatic risks during maintenance, safety interlocks, and lockout/tagout (LOTO). The course builds awareness, decision-making skills, and safe work habits needed in high-tech manufacturing environments.

Click here to watch a video about the course. Visit Intelitek.com to learn more.

Duration: 16 Hours

Part number: 88-3031-0000

Version: 0.9.0.2

What’s in a microchip?

In this course, students will get a broad look at the world of semiconductor manufacturing, from the atomic structure of tiny silicon devices to the global impact of geopolitical forces on multinational companies: and everything in between.

Duration: 16 Hours

Part number: 88-3025-0000

Version: 0.0.0.2

Visión artificial y control de calidad (Curso de laboratorio n.º 2) con Cognex In-Sight 2000 se basa en el contenido del primer curso de laboratorio y enfatiza los sistemas de visión en líneas de producción automatizadas y las herramientas de software de visión que ayudan en la inspección de piezas, productos, y embalaje.

Número de catálogo: 77-8089-0000ES

Versión: 1.0.0.0

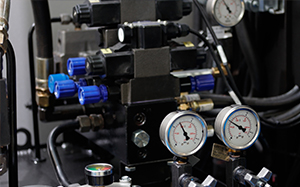

The Pneumatics Technology 1 module introduces the principles of pneumatics and pneumatically controlled systems commonly used in automated manufacturing environments.

This module features pneumatic simulation software that allows you to create, modify, operate and observe simulated industrial grade pneumatic and electro-pneumatic devices and circuits. You connect different components, change physical parameters and observe system responses.

The module emphasizes basic skills in operating simulation software and industrial components. This module also includes applied science experiments to demonstrate the physical principles of air power.

Catalog number: 88-8070-0010

[Ver: 2.0.1.0] (NIMS accredited!)

- Teacher: David Crowell

The Pneumatics Technology 2 module introduces students to advanced principles and components of pneumatics and pneumatically controlled systems commonly used in automated manufacturing environments. Students are also introduced to timing diagrams and the logic functions AND and OR, and implement them in pneumatic circuits.

Students create, modify, operate and observe simulated pneumatic devices and circuits. Students test and troubleshoot pneumatic circuits by connecting components, changing physical parameters and observing system responses. The module focuses on pneumatics circuits and industrial applications.

Catalog number: 88-8070-0020

[v 2.1.1.2]

- Teacher: David Crowell

This module is the third in the series of Pneumatics Technology modules, which enable students to grasp the fundamentals of pneumatic and electro-pneumatic controlled systems (pneumatic systems controlled electrically) commonly used in modern automated manufacturing environments. Virtual and hands-on activities challenge students to design and build pneumatic circuits with simulation software and actual components. In this module, students are exposed to the function and operation of electric/electro-pneumatic components such as switches, relays, timers, electrical push buttons, solenoid operated valves and proximity sensors. Using graphic simulations and animations, students create, modify, operate and observe simulated pneumatic and electro-pneumatic devices and circuits. Students connect different components, change physical parameters and observe system responses.

Catalog Number: 88-8070-0030

[v 1.3.1.2]

The Hydraulics Technology modules introduce students to the principles of hydraulics and the use of fluid power in automated manufacturing environments. In these modules, students use software to create, modify, operate and observe simulated hydraulic and electro-hydraulic devices and circuits. Students also use the hydraulics training panel with a wide assortment of industrial grade hydraulic components.

Students connect components on the panel in order to control a variety of typical industrial hydraulic applications. Students connect different components, change physical parameters and observe system responses. The combination of software and industrial equipment allows students to test and troubleshoot simulated circuits before hardware connections are made.

In the hydraulics module students design solutions for industrial hydraulic applications with emphasis on real industrial concerns, such as power losses across components, system overheating and optimized hydraulic power. Hydraulics Technology 1 emphasizes the use of simulation software and the design of basic hydraulic circuits. This module also includes applied science experiments to demonstrate the physical principles of fluid power.

Catalog number: 88-8071-0010

[Ver: 1.5.0.0]

- Teacher: David Crowell

The Hydraulics Technology modules introduce students to the principles of hydraulics and the use of fluid power in automated manufacturing environments. In these modules, students use software to create, modify, operate and observe simulated hydraulic and electro-hydraulic devices and circuits. Students also use a hydraulics training panel with a wide assortment of industrial grade hydraulic components.

In Hydraulics Technology 3: Advanced Hydraulics and Electro-hydraulics, students are exposed to the function and operation of advanced components and circuits involving switches, relays, timers, electrical push buttons, solenoid operated valves and proximity sensors. In addition, students learn the critical skill of how to connect circuits by reading schematic diagrams.

Catalog number: 88-8071-0030

[Ver: 1.3.1.2]

The Hydraulics Technology modules introduce students to the principles of hydraulics and the use of fluid power in automated manufacturing environments. In these modules, students use software to create, modify, operate and observe simulated hydraulic and electro-hydraulic devices and circuits. Students also use the hydraulics training panel with a wide assortment of industrial grade hydraulic components.

Hydraulics Technology 2 focuses on electro-hydraulics, using a computer interface control unit to enable software control and online graphic tracking of the hydraulics panel. Electro-hydraulic systems use electrical circuits to operate hydraulic components.

Catalog number 88-8071-0020

[Ver: 2.1.2.3]

- Teacher: David Crowell

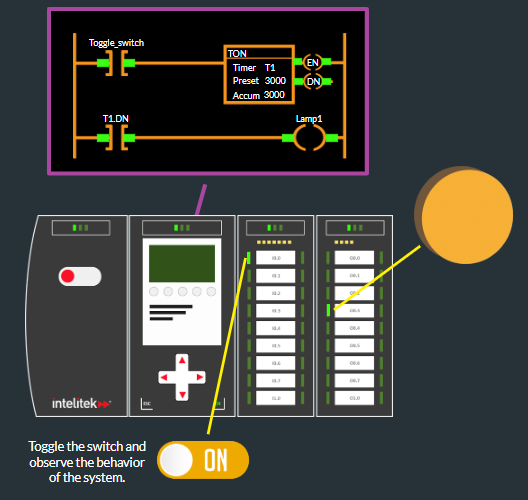

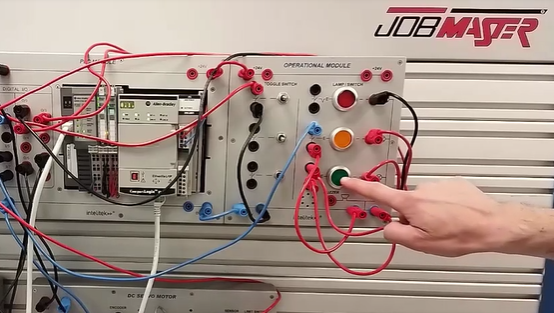

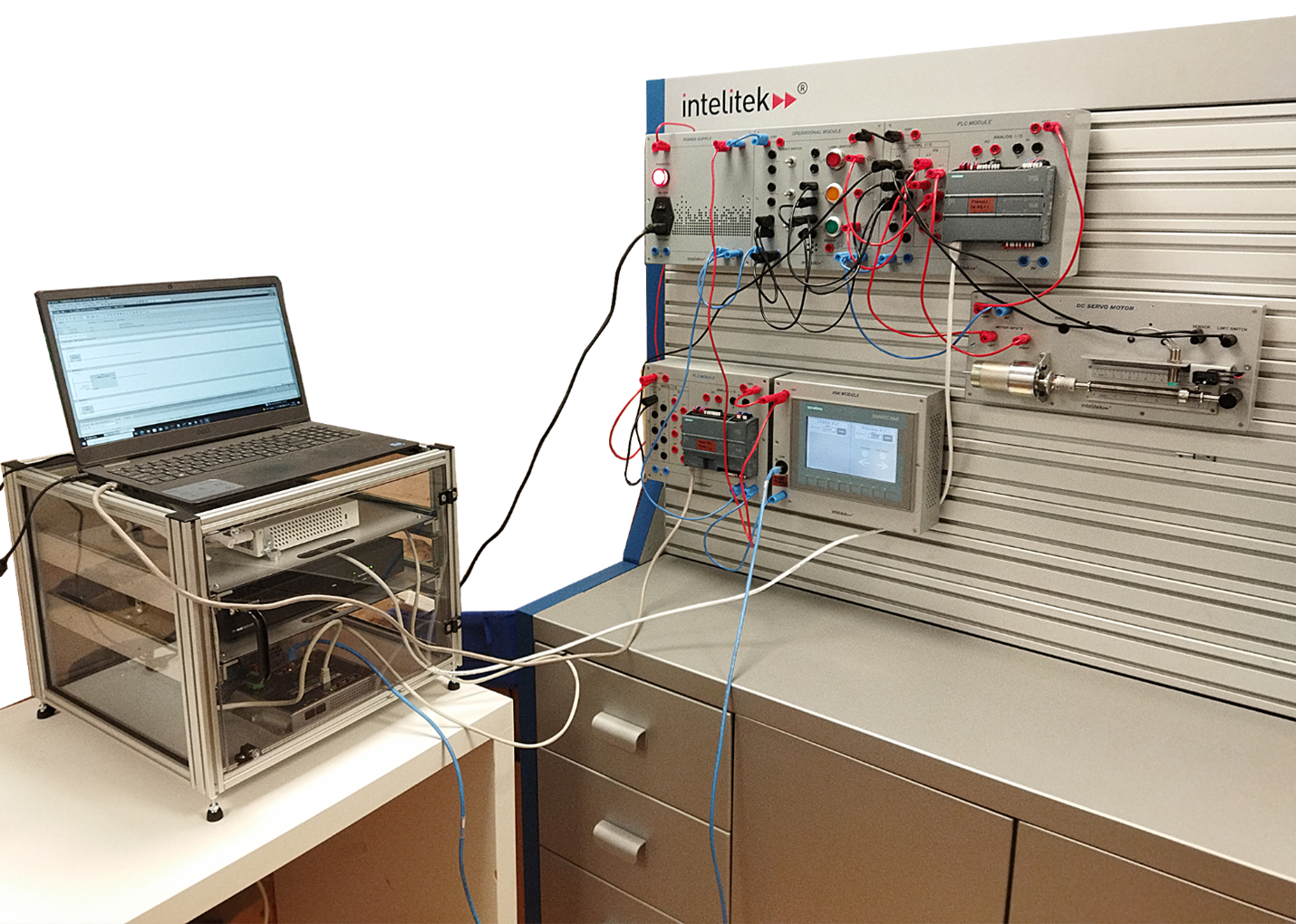

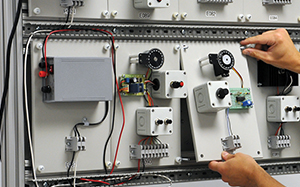

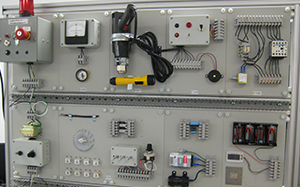

The PLC Technology 1: Fundamentals of Ladder Logic module is the first in a series of four modules that teach about PLC technology. In this module, students learn how to program and use PLCs in industrial applications that require electrical control. The PLC modules feature powerful PLC simulation control software that allows students to program a PLC and simulate industrial applications.

The module includes the testing of input and output responses to ladder diagrams students program.

PLC Technology 1: Fundamentals of Ladder Logic emphasizes the fundamentals of PLC theory and basic programming.

Cat No. 88-8220-0010

[Ver: 1.3.1.1]

In the PLC Technology 2: Advanced Ladder Logic module, you learn how to program and use PLCs in industrial applications that require electrical control. The PLC modules feature software, which allows you to program a PLC and simulate industrial applications. The module includes the testing of input and output responses to ladder diagrams you have programmed. The combination of graphic simulation software with PLC hardware enables you to test and correct control programs both online and offline.

PLC Technology 2: Advanced Ladder Logic focuses on advanced PLC programming.

88-8220-0020

[Ver: 1.2.1.0]

Students learn how to program and use PLCs in industrial applications that require electrical control. The PLC modules feature software that allows students to program a PLC and simulate industrial applications. The module includes the testing of input and output responses to ladder diagrams programmed by students.

In PLC Technology 3: PLC-Controlled Pneumatic Systems, students learn how to control pneumatic systems using a PLC. Basic pneumatic terminology is introduced and explained, and the student simulates the operation of pneumatic components.

Catalog number: 88-8220-0030

[Ver: 2.1.0.0]

In PLC Technology 4: PLC-Controlled Hydraulic Systems, students learn how to control hydraulic systems using a PLC. Basic hydraulic terminology is introduced and explained, and the student simulates the operation of hydraulic components.

Catalog Number: 88-8220-0040

[Ver: 2.1.0.0]

This 6-hour course is designed for students who already have knowledge in basic PLC programming. The supplement introduces the students to the Siemens PLC system with the S7-1200 hardware and STEP 7 TIA Portal software.

Cat. number: 77-8210-0050

[Ver: 1.0.0.0]

The PLC Technology 1: Fundamentals of Ladder Logic module is the first in a series of four modules that teach about PLC technology. In this module, students learn how to program and use PLCs in industrial applications that require electrical control. The PLC modules feature powerful PLC simulation control software that allows students to program a PLC and simulate industrial applications.

The module includes the testing of input and output responses to ladder diagrams students program. The combination of graphic simulation software with PLC virtual hardware enables students to test and correct control programs both online and offline.

PLC Technology 1: Fundamentals of Ladder Logic emphasizes the fundamentals of PLC theory and basic programming.

Cat. No. 88-8210-0010

[Ver: 2.0.0.0]

In the PLC Technology 2: Advanced Ladder Logic module, you learn how to program and use PLCs in industrial applications that require electrical control. The PLC modules feature software, which allows you to program a PLC and simulate industrial applications. The module includes the testing of input and output responses to ladder diagrams you have programmed. The combination of graphic simulation software with PLC hardware enables you to test and correct control programs both online and offline.

PLC Technology 2: Advanced Ladder Logic focuses on advanced PLC programming.

[Ver: 2.0.0.0]

88-8210-0020

Students learn how to program and use PLCs in industrial applications that require electrical control. The PLC modules feature software, which allows students to program a PLC and simulate industrial applications. The module includes the testing of input and output responses to ladder diagrams programmed by students. The combination of graphic simulation software with PLC virtual hardware enables students to test and correct control programs both online and offline.

In PLC Technology 3: PLC-Controlled Pneumatic Systems, students learn how to control pneumatic systems using a PLC. Basic pneumatic terminology is introduced and explained, and the student simulates the operation of pneumatic components.

[Ver: 2.0.0.0]

Catalog number: 88-8210-0030

Students learn how to program and use PLCs in industrial applications that require electrical control. The PLC modules feature software, which allows students to program a PLC and simulate industrial applications. The module includes the testing of input and output responses to ladder diagrams programmed by students. The combination of graphic simulation software with PLC virtual hardware enables students to test and correct control programs both online and offline.

In PLC Technology 4: PLC-Controlled Hydraulic Systems, students learn how to control hydraulic systems using a PLC. Basic hydraulic terminology is introduced and explained, and the student simulates the operation of hydraulic components.

[Ver: 2.0.0.0]

Catalog Number: 88-8210-0040

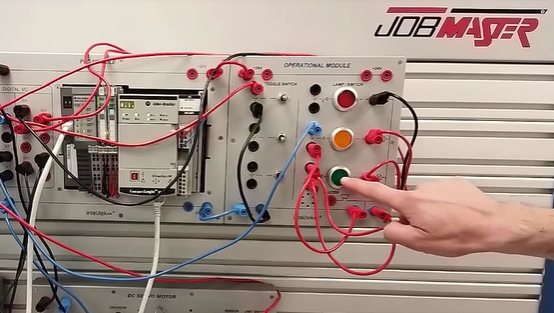

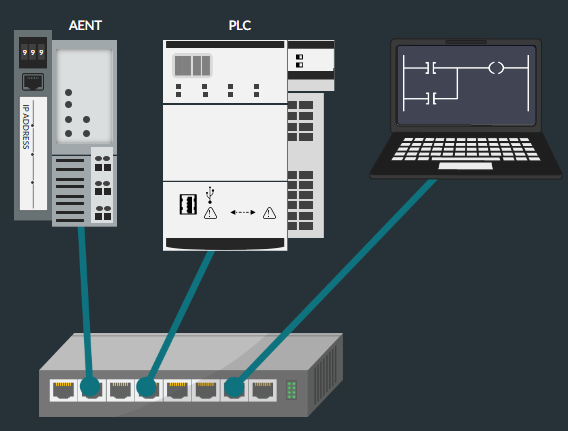

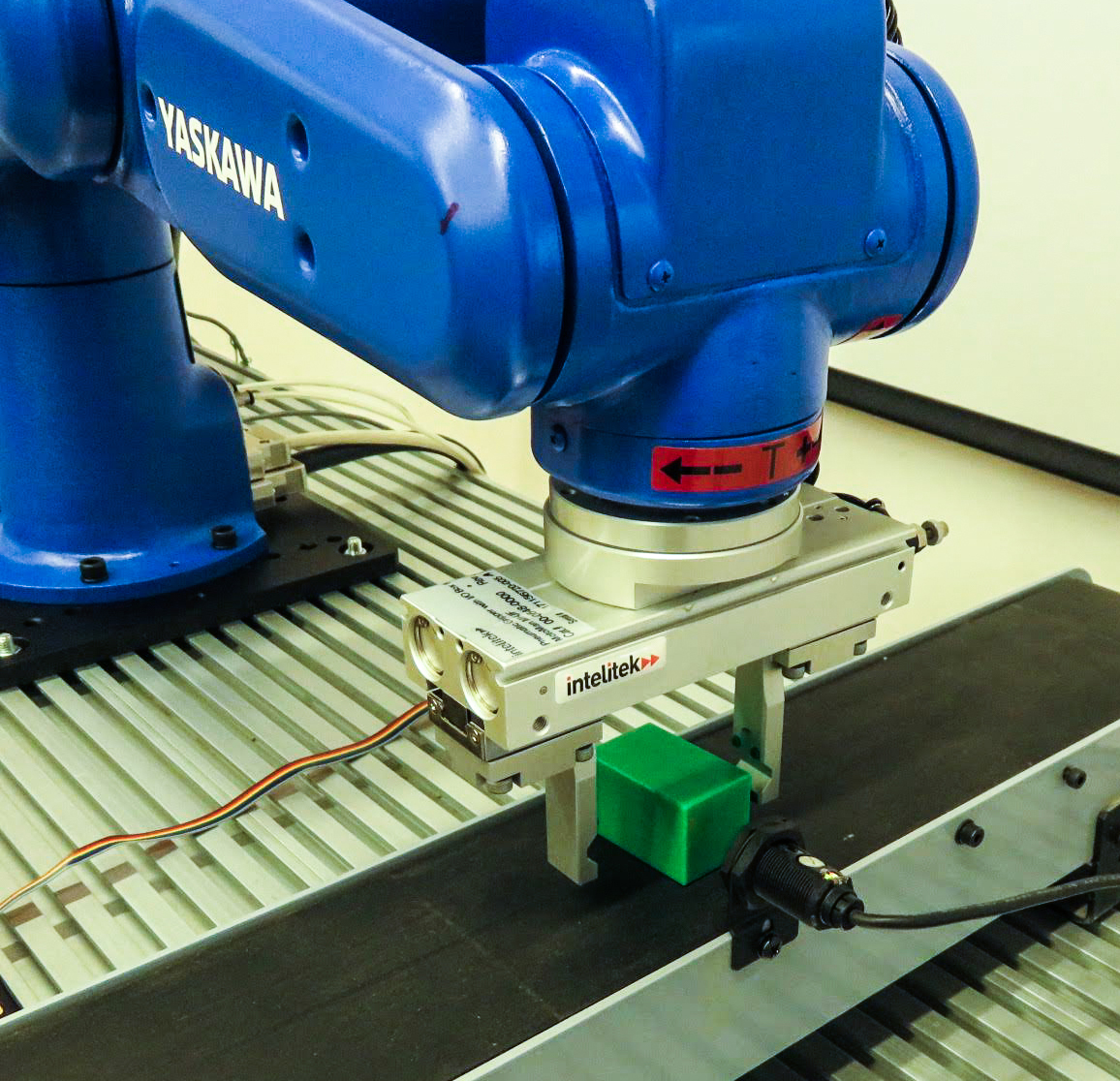

The PLC Technology with the Allen-Bradley CompactLogix is a four-course series focusing on the foundational building blocks that are required to understand how PLCs work and how they are programmed. The courses feature hardware and software used in the automation industry: Rockwell’s Allen-Bradley CompactLogix 5380 PLC and the Studio 5000 Logix Designer PLC programming package.

The first course in the series emphasizes the basics of PLC theory and essential ladder logic programming concepts. The course concludes with a series of PLC programming projects.

Catalog Number 88-8230-0010

Version 1.1.4.0

- Teacher: David Crowell

The PLC Technology with the Allen-Bradley CompactLogix is a four-course series focusing on the foundational building blocks that are required to understand how PLCs work and how they are programmed. The courses feature hardware and software used in the automation industry: Rockwell’s Allen-Bradley CompactLogix 5380 controller and the Studio 5000 Logix Designer PLC programming package.

The second course in the series focuses on PLC memory, timers, counters, and important bit instructions. The course also includes a number of PLC programming projects.

Catalog number: 88-8230-0020

Version: 1.1.0.0

- Teacher: David Crowell

The PLC Technology with the Allen-Bradley CompactLogix is a four-course series focusing on the foundational building blocks that are required to understand how PLCs work and how they are programmed. The courses feature hardware and software used in the automation industry: Rockwell’s Allen-Bradley CompactLogix 5380 controller and the Studio 5000 Logix Designer PLC programming package.

The third course in the series focuses on ladder diagram comparison and mathematical instructions. The course also includes a number of PLC programming projects.

Catalog number: 88-8230-0030

Version: 1.1.1.0

PLC Technology with the Allen-Bradley CompactLogix is a four-course series focusing on the foundational building blocks that are required to understand how PLCs work and how they are programmed. The courses feature hardware and software used in the automation industry: Rockwell’s Allen-Bradley CompactLogix 5380 controller and the Studio 5000 PLC programming suite, including both Logix Designer (for PLC programming) and View Designer (for HMI screen setup).

The fourth course in the series focuses on PLC communication, the Allen-Bradley Human Machine Interface (HMI), and various advanced programming concepts and techniques. The course also includes a number of PLC programming projects.

*New* Now includes an experiment guide for PLC-controlled pneumatic systems.

Catalog number: 88-8230-0040

Version: 1.2.0.0

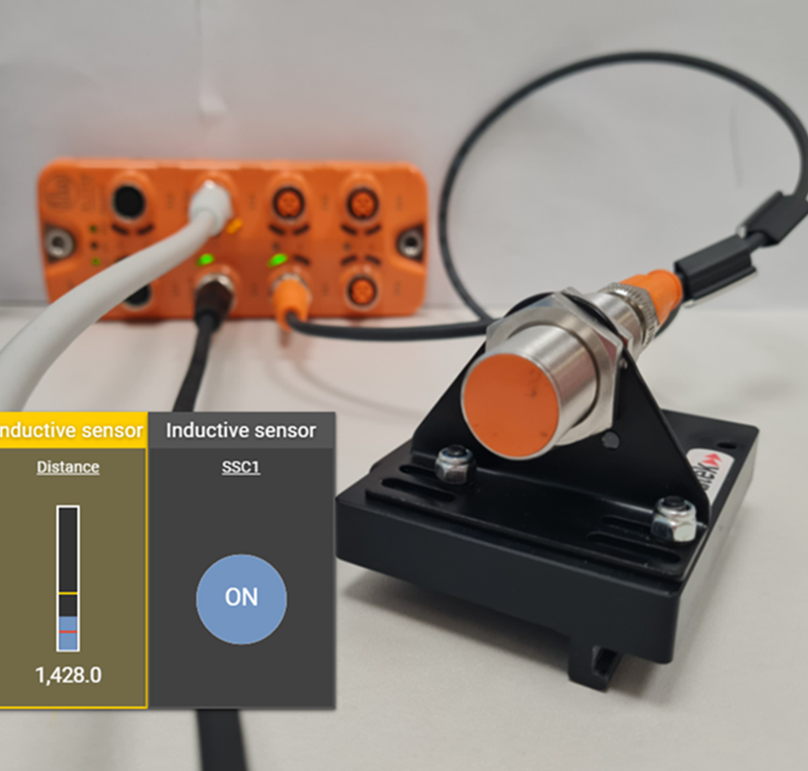

Featuring devices that use cutting-edge IO-Link communication technology, this course surveys many of the smart sensors and output devices that are available in the manufacturing industry today. Also covered in the course are invaluable Industry 4.0-related concepts such as communication protocols, remote cloud monitoring, sensor network architecture, and smart asset tracking. Students will also learn how to choose the best sensor for any given automation application.

The course also includes various lab activities that incorporate smart device hardware with local and remote monitoring software.

Catalog number: 88-3300-0001

Version number: 1.1.3.0

- Teacher: David Crowell

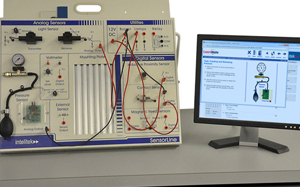

The Sensor Technology module introduces students to the use and applications of sensor technology in manufacturing processes. In the Sensor Technology module, the student designs and assembles basic control circuits, to activate and control both analog and digital sensors on a training panel in various configurations.

Students experiment with a variety of elements for triggering the sensors, such as a light source, a light filter, an optic fiber cable, magnets, an air pump, and aluminum, iron, wood, and plastic blocks. Students connect different components, change physical parameters and measure sensor response.

Cat. Number 77-8012-0000

[Ver: 2.0.2.0]

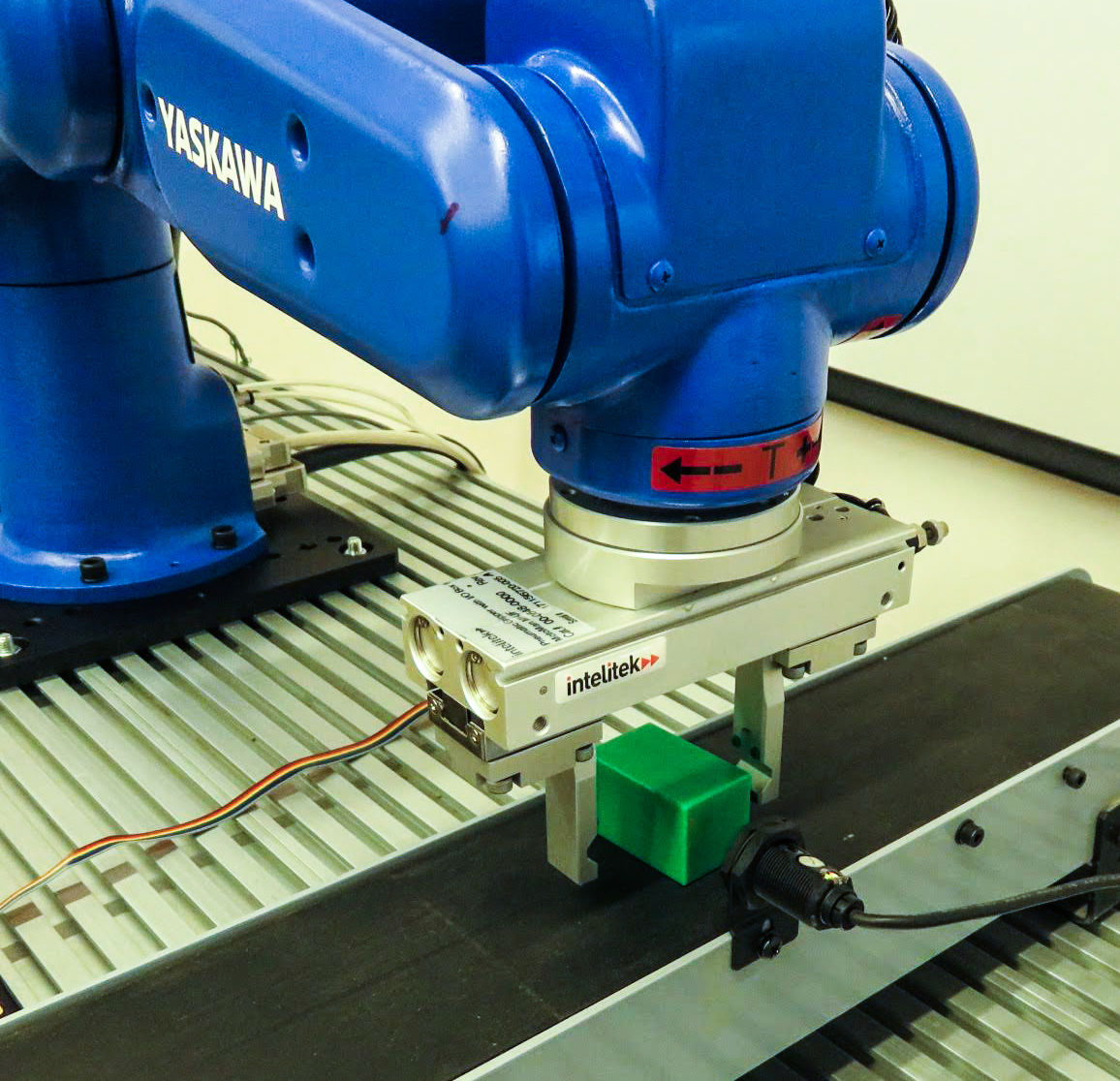

The Machine Vision and Quality Control lab course uses a Cognex Vision Sensor and Cognex In-Sight Explorer software with the embedded image processing engine in the camera. Students learn to operate and program the technology and connect cameras and computers to provide the image interpretation and visual feedback needed for vision systems. The curriculum provides instruction on the use and setup of the Cognex digital color camera and integration of the vision system into quality control and manufacturing processes.

Catalog Number: 88-8087-0000

[Ver: 2.0.2.0]

- Teacher: David Crowell

Machine Vision and Quality Control (Lab Course #2) with the Cognex In-Sight 2000 builds on the content of the first lab course and emphasizes vision systems in automated production lines and the vision software tools that aid in the inspection of parts, products, and packaging.

Catalog number: 88-8089-0000

Version: 2.0.1.0

- Teacher: David Crowell

Catalog number: 77-3030-0000

Version: 1.0.0.0

Automatic identification systems enable direct entry of data into a computer system, programmable logic controller (PLC) or other microprocessor-controlled device without using a keyboard. AutoID technologies provide a quick, accurate and cost-effective way to track items, collect and enter data, and encode a wide range of information, from a simple detail to comprehensive statistics about an item or person.

In the Automatic Identification Systems module, students are introduced to the most popular AutoID technologies: bar codes, magnetic stripe cards, smart cards, biometric technologies and radio frequency (RF). Students observe how different automatic identification technologies offer different solutions to data collection and storage problems. Students determine the advantages/disadvantages, features and typical applications of each technology.

Cat. Number 88-3051-0000

[Ver: 2.0.0.0]

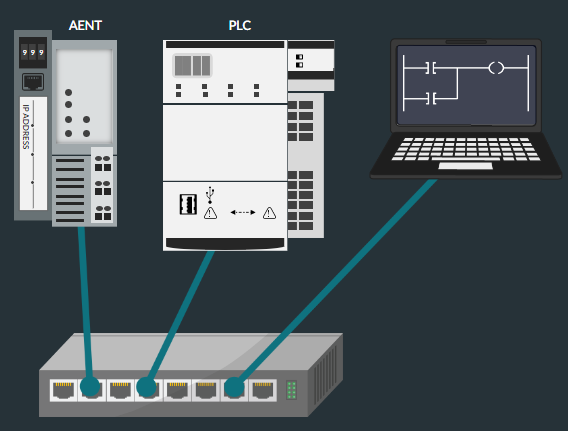

In a world where

cyberthreats are ever-present, a manufacturing enterprise must do everything in

its power to protect its valuable assets and information from external attack. The

Intelitek Industrial Cybersecurity Experimentation

Package with the JobMaster Mechanical Training Bench is meant to

provide a scaled-down, smart factory network coupled with an accompanying

informational technology (IT) network equipped with various cybersecurity features.

The experimentation kit is usable in an educational setting, while still

providing would-be technicians and factory managers with authentic,

industry-recognized hardware and software.

Category: Industry 4.0

Catalog number: 88-8301-0012

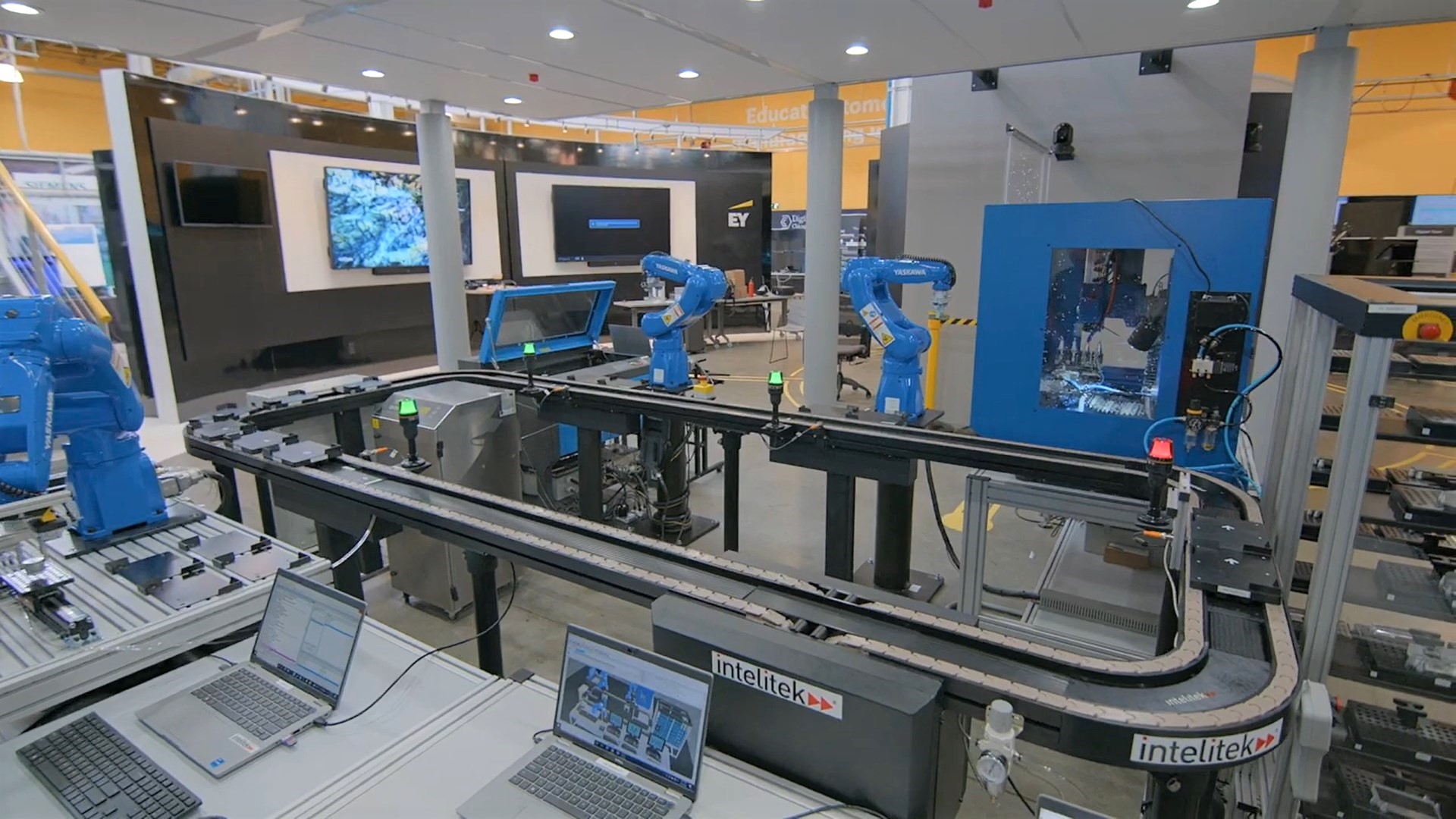

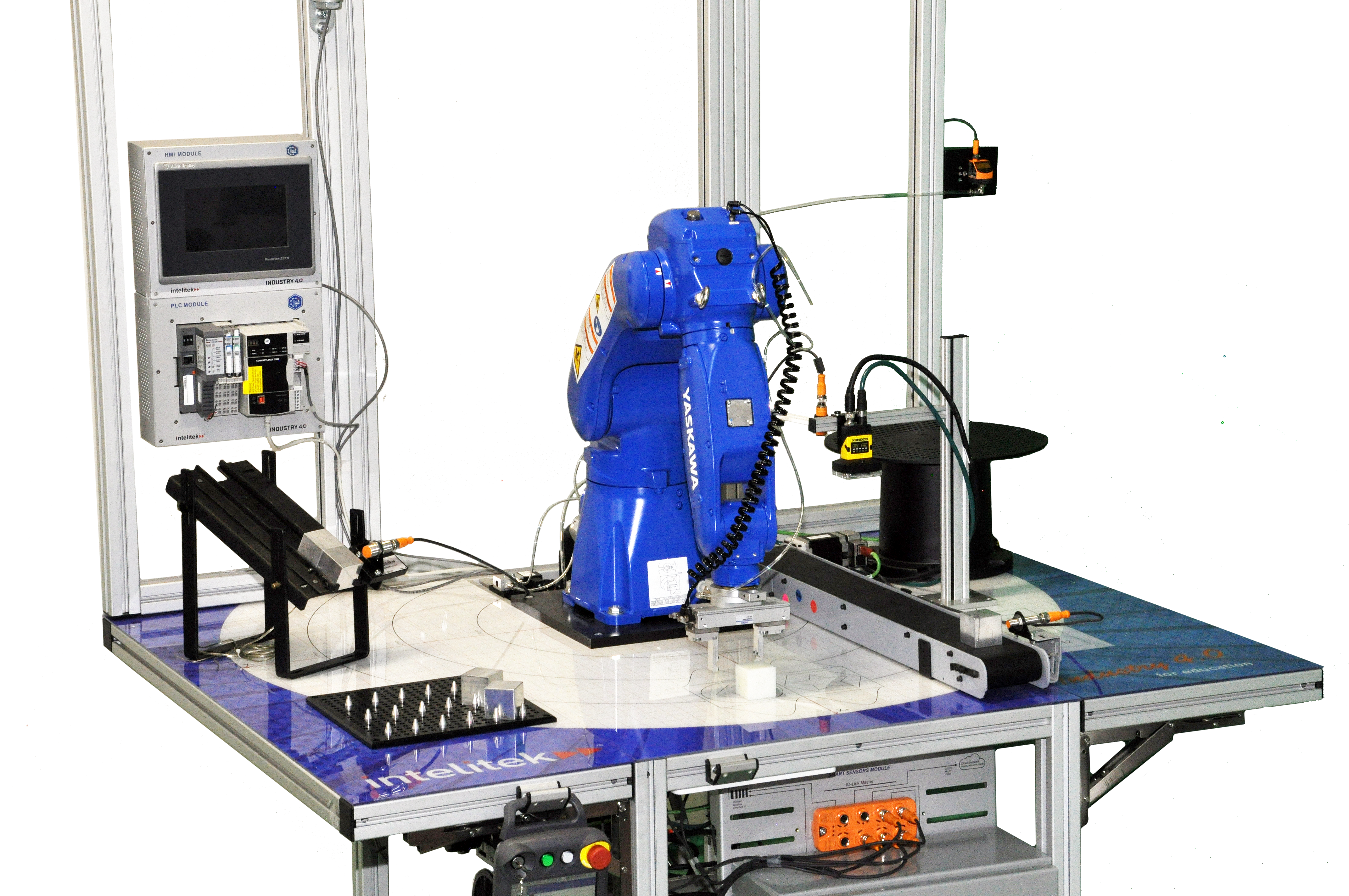

Computer Integrated Manufacturing with OpenMES allows course participants to explore and operate a fully equipped industrial CIM system. With OpenMES manufacturing execution and simulation software, students can monitor system statuses, introduce customer and manufacturing orders, define processes, and optimize production.

Part 2 of this series builds upon the previous course and delves into different manufacturing concepts such as mass production, robotic systems, location planning, QC devices, part feeding, assembly, purchasing orders, MRPs, and databases.

In the course, students will learn how to design, set up and operate CIM cells that contain three to four workstations and learn about the devices used in these CIM cells and the parts that they can manufacture. In addition, students will be taught about the OpenCIM databases that play a key role in production management and storage of all the data that is collected before, during, and after production.

Course participants will also get a chance to learn about the vital aspects of a CIM production cycle, from customer order and inventory control, through automated manufacturing of materials into finished parts, to quality inspection and final delivery.

Catalog number: 88-3018-0000

[Ver: 1.0.1.0]

Computer Integrated Manufacturing with OpenMES allows course participants to explore and operate a fully equipped industrial CIM system. With OpenMES manufacturing execution and simulation software, students can monitor system statuses, introduce customer and manufacturing orders, define processes, and optimize production.

Part 1 of this course series introduces the core concepts, procedures, and stages of CIM production as well as the main components and devices in a basic CIM cell. Activities include parts and production flow, storage setup, production planning, machine definition, defining product parts and processes, timing and optimization, and integrated production.

Students will also get a chance to learn about the vital aspects of a CIM production cycle, from customer order and inventory control, through automated manufacturing of materials into finished parts, to quality inspection and final delivery.

Catalog number: 88-3017-0000

[Ver: 1.0.0.0]

Explore the evolving landscape of the modern supply chain with the comprehensive Logistics and Warehousing for Industry 4.0.

Covering essential topics such as supply chain operations, warehouse management, and tracking technologies, this course offers a systematic approach for learning Industry 4.0 logistics.

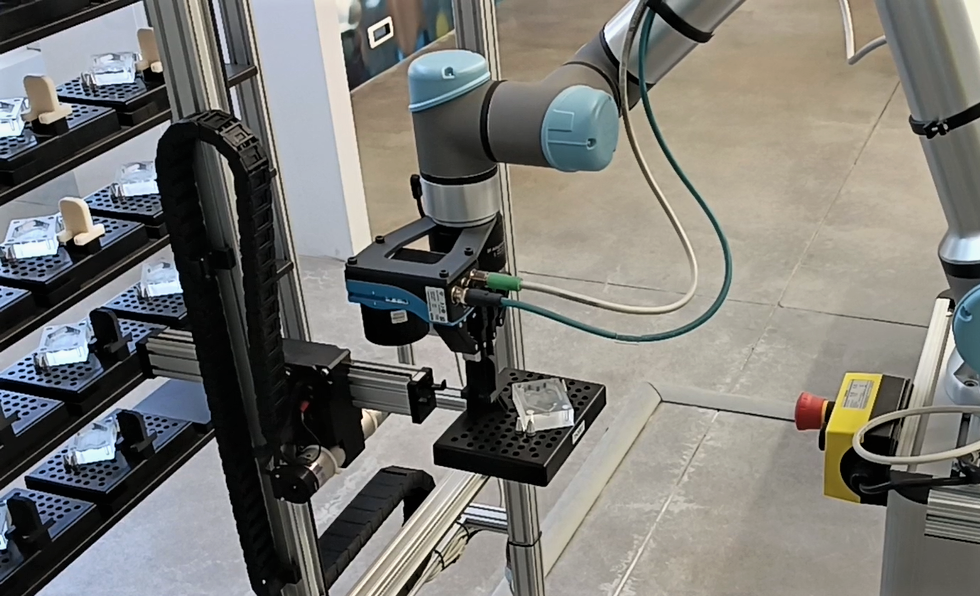

Participants will get hands-on experience with autonomous mobile robots (AMRs), collaborative robots (cobots), automatic storage and retrieval systems (ASRS), and machine vision guidance, gaining the knowledge required to harness these technologies effectively.

The course also delves into sensor applications, safety protocols, and the role of the Internet of Things (IIoT) in smart warehousing. Students also examine how logistics software is used to optimize logistics operations.

Catalog number: 88-3301-0022

Version number: 1.0.0.0

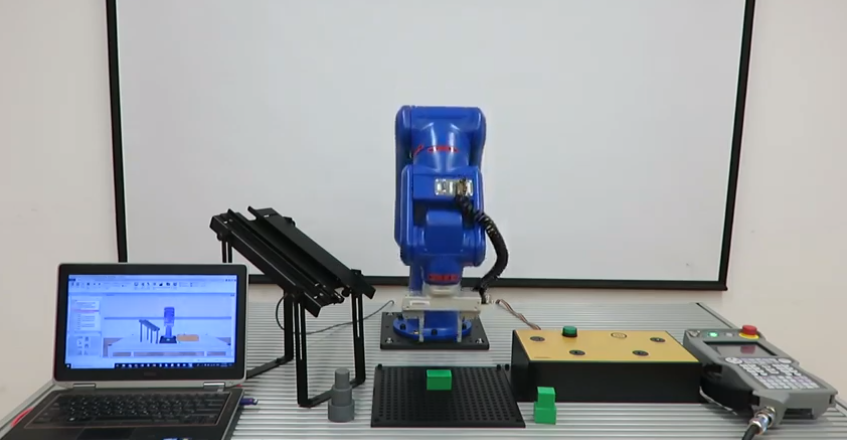

The Flexible Manufacturing System (FMS) module exposes students to automation and industrial applications by combining CNC technology with robotics and materials handling. Students develop and edit programs, record precise robotic positions, accurately mill parts, and synchronize mill and robot operation. Students gain "virtual hands-on" experience in CNC and robot programming, especially in I/O commands. Students design solutions for industrial FMS applications with emphasis on real industrial concerns, such as optimized CNC and robotic programming and accurate machine tending.

RoboCell for ER9 is the software used in this virtual-only course.

Catalog number: 77-3022-0000

[Ver: 2.1.1.0]

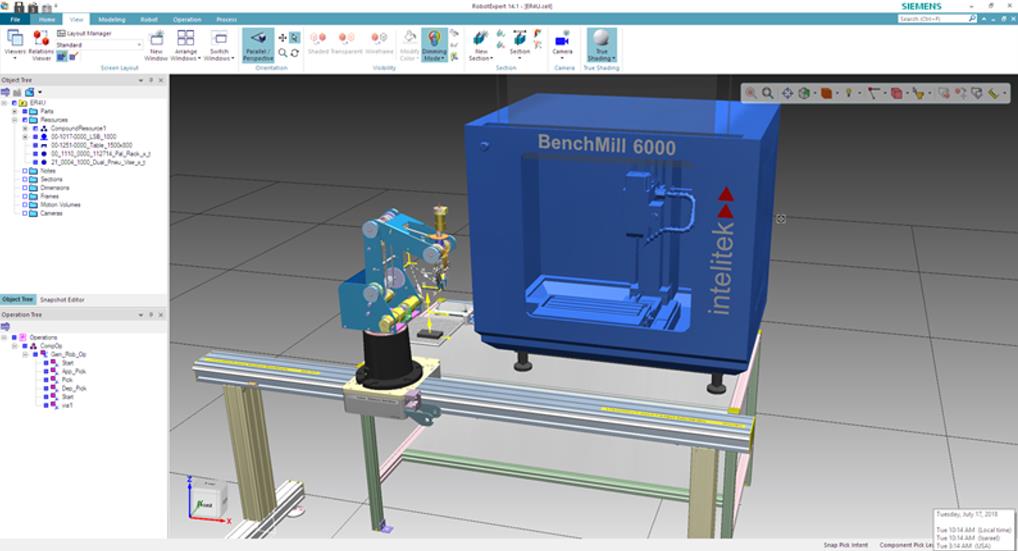

RobotExpert is a simulation and offline programming software that enables manufacturers to perform complete 3D modeling, visualization and simulation of their automation systems, including robots, tooling and peripheral equipment. In this course, we will learn the basics of how to use this full-featured program and observe how it enables manufacturers to optimize their production processes while eliminating waste and extra costs.

Catalog number: 77-8401-0001

Course version number: 1.1.0.1

Advanced Manufacturing Processes with RobotExpert is a continuation of the introductory RobotExpert Course. Siemens Tecnomatix RobotExpert is a simulation and programming software that enables manufacturers to perform complete 3D modeling, visualization, and simulation of their automation systems, including robots, tooling, and peripheral equipment. In this course, students will learn about the more advanced features of the software.

Specifically, this course delves into the following concepts:

- Collision Detection and Prevention

- Modification of Location Attributes

- Offline Programming (OLP)

- Cell Layout Optimization

- Robot Controller Selection and Setup

- Creating Robotic Programs

Catalog Number: 77-8401-0002

Version: 1.0.1.0

The Computer Integrated Manufacturing 1 module contains two workstations and is based on an educational system which fully replicates an industrial CIM using the OpenCIM Software. The activities in this module include parts and production flow, storage setup, production planning, machine definition, defining product parts and processes, timing and optimization and integrated production.

This module, introduces the basic concepts, procedures and key stages of CIM production as well as the main components and devices in a basic CIM cell.

Students will learn about all the aspects of a CIM production cycle, from customer order and inventory control, through automated manufacturing of materials into finished parts, to quality inspection and final delivery.

Catalog number: 88-3015-0000

[Ver: 2.0.1.1]

The Computer Integrated Manufacturing 2 module contains three to four workstations and is based on an educational system which fully replicates an industrial CIM using the OpenCIM Software.

This module assumes prior knowledge of OpenCIM software and the basic concepts and procedures that were covered in the CIM 1 module. The activities described in this module include mass production, robotic systems, location planning, QC devices, part feeding, assembly, purchasing orders, MRP and CIM databases.

In this module students will learn how to design, set up and operate CIM cells that contain three to four workstations and learn about the devices used in these CIM cells and the parts that they can manufacture. In addition, students will learn about the OpenCIM databases that play a key role in production management and storage of all the data that is collected before, during and after production.

Cat. Number: 88-3016-0000

[Ver: 2.0.2.0]

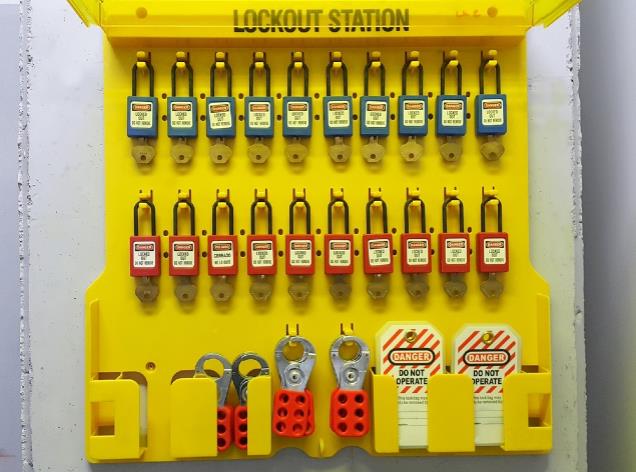

Electrical Circuits (EA01A) introduces students to fundamental electrical concepts including lockout/tagout and safety, connecting circuits and measuring voltage and current. The skills-based curriculum presents hands-on activities using a digital multimeter and other industrial-grade electrical components mounted on six Flexponent™ panels which attach to the JobMaster™ Learning Station or the new CTE Portable Electric Circuits Trainer. Electrical Circuits (EA01A) is the first in the four-course Basic Power Electricity series, which teaches the introductory electrical skills essential for success in automated manufacturing.

Cat. Number 88-EA01A-0000

[Ver: 2.1.2.0]

Resistors and Conductors (EA01B) teaches vital skills for troubleshooting and testing circuits including measuring resistance, calculating and measuring wire size, determining losses in a wire, and drawing resistor symbols. The skills-based curriculum builds on the concepts learned in the prerequisite course: Electrical Circuits (EA01A). Adding one new Flexponent™ panel to the Basic Power Electricity series, Resistors and Conductors (EA01B) presents hands-on activities using a industrial-grade resistors, potentiometers, rheostats and coils.

Cat. Number 77-EA01B-0000

[Ver: 2.0.0.0]

LCR Circuits (EA01C) teaches the relationships between electrical properties such as inductance, capacitance and reactance. The skills-based curriculum builds on concepts learned in the prerequisite Resistors and Conductors (EA01B) course. Using the same components they will find in industrial environments, including relays, contactors, capacitors and inductors, students learn to determine capacitance, assemble an electromagnet, induce voltage and operate transformers.EA01C includes five additional Flexponent™ panels for use with the JobMaster™ Learning Station in eleven hands-on activities.

Cat. Number 77-EA01C-0000

[Ver: 2.0.0.0]

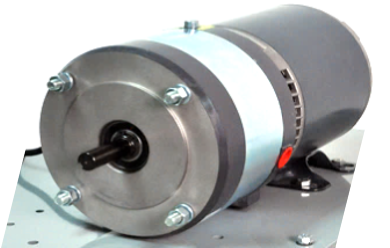

Motors and Generators (EA01D) delivers a complete understanding of phase relationships and the practical operation of motors and generators through activities including operating AC and DC generators, operating a series motor and demonstrating reactance and impedance. The skills-based curriculum builds on concepts learned in the prerequisite LCR Circuits (EA01C) course. Motors and Generators (EA01D) adds interactive content for eight additional hands-on activities using the Basic Power Electricity equipment.

Cat. Number 77-EA01D-0000

[Ver 2.0.2.0]

Overload/Overcurrent Protection and Monitoring (EA02) follows the four-course Basic Power Electricity series. This course guides the student through various hands-on activities regarding important safety measurements. The student learns skills such as drawing and reading circuit protection symbols, working with fuses, sizing overload heaters and circuit breakers, installing a three-phase line monitor and troubleshooting and performing preventative maintenance fuse blocks. As the students work through the curriculum, they gain experience and then demonstrate their skills to an instructor using industrial grade electrical safety components attached to the Jobmaster Learning Station.

Cat. Number 77-EA02-0000

[Ver: 2.0.1.0]

Transformers (EA03) introduces students to the various aspects of transformers. They not only learn how to apply transformer principles but also have to work through a number of hands-on activities and learn how to inspect, test, troubleshoot, disconnect, replace and reconnect transformers. Students learn how to calculate secondary voltage, primary current, primary and secondary current KVA, transformer efficiency and how to apply these calculations. The skills-based curriculum presents hands-on activities using industrial grade electrical components mounted on a three-phase power control panel (PC06) and three-phase transformer panel (E003) which attach to the Jobmaster Learning Station.

Cat. #77-EA03-0000

[Ver: 2.0.0.0]

Electric Motors (EA04) guides students through hands-on activities using common industrial motors, including three-phase, split-phase and capacitor-start motors. From wiring motor circuits to preventive maintenance and troubleshooting, students gain practical experience in all aspects of industrial motor operation, including connecting and operating a three-phase motor, troubleshooting a capacitor-start motor and testing motors with adjustable loads The skills-based curriculum presents hands-on activities using industrial grade electrical components mounted on ten Flexponent™ panels which attach to the JobMaster Learning Station.

Cat. Number 88-EA04-0000

[Ver: 2.0.1.0]

Electromagnetic Motor Starters (EA07) guides students through hands-on activities using industrial motor controls. From wiring motor control circuits to troubleshooting, students gain practical experience in all aspects of industrial motor control, including testing and resetting overload protection, operating a three-phase reversing starter and troubleshooting a three-phase motor control circuit. The skills-based curriculum presents eight critical skills using industrial magnetic starters, relays, and START-STOP motor control components mounted on six included Flexponent™ panels which attach to the JobMaster Learning Station.

Cat. Numbe 77-EA07-0000

[Ver: 2.0.0.0]

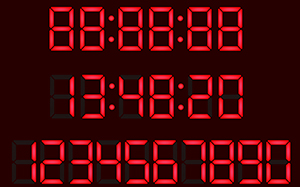

Relays, Timers & Time Delay Relays (EA08) delivers hands-on skills in installing, programming and maintaining control devices used in industrial electric circuits. Relays, Timers & Time Delay Relays (EA08) is an add-on to Electromagnetic Motor Starters (EA07), covering eight additional skills including Connecting and Programming Analog On-Delays and Off-Delay Relays, Using Digital Relays and Motors, Troubleshooting Relays. The skills-based curriculum presents hands-on activities using a digital relay and an electronic timer mounted on the two included Flexponent™ panels which attach to the JobMaster(r) Learning Station.

Cat. Number 77-EA08-0000

[Ver: 2.0.0.0]

Pilot Devices (EA09) delivers hands-on skills in installing, operating and troubleshooting pilot devices used in electric control circuits. Pilot Devices (EA09) is an add-on to Electromagnetic Motor Starters (EA07), covering ten additional skills including connecting and operating photoelectric sensors with fiber optics, capacitive and inductive proximity switches, limit switches, pressure switches, liquid level switches, and magnetic reed switches. The skills-based curriculum presents hands-on activities using industrial-grade components mounted on the four included Flexponent™ panels which attach to the JobMaster(r) Learning Station.

Cat. Number 77-EA09-0000

[Ver: 2.0.0.0]

Solid-State Starters (EA11) introduces the student to the advantages of solid state starters, why they are replacing magnetic motors in various industries and how to apply solid state starter principles. They learn the skills and gain experience in connecting, operating, testing and troubleshooting solid state starters. Throughout the curriculum the student works through various hands-on activities using industrial grade components attached to various panels such as the transformer panel (E012) and the solid state starter panel (E024) which attach to the Jobmaster Learning Station.

Cat. Number 77-EA11-0000

[Ver: 2.0.0.0]

Electronic Motor Drives (EA12) instructs students on the use of these drives through several practical activities. Students learn why the common AC motors are the drivers of industry, and will gain experience working with them. In this course they will study the principles of variable frequency drives and then learn how to connect, set up, adjust, test, operate and troubleshoot variable frequency drives. The student gains these important skills by working with an industry-standard Variable Frequency Drive and Flexponent™ panels which attaches to the JobMaster Learning Station.

Cat. Number 77-EA12-0000

[Ver: 2.1.0.0]

In DC Motor Control (EA16), students will gain practical experience by working through several hands-on activities. They will study DC drive principles and then learn how to connect, set up, operate and troubleshoot a DC drive. They will work with several Flexponent™ panels, including the DC Motor Panel (E034) which attaches to the JobMaster Learning Station.

Cat. Number 77-EA16-0000

[Ver: 2.0.0.0]

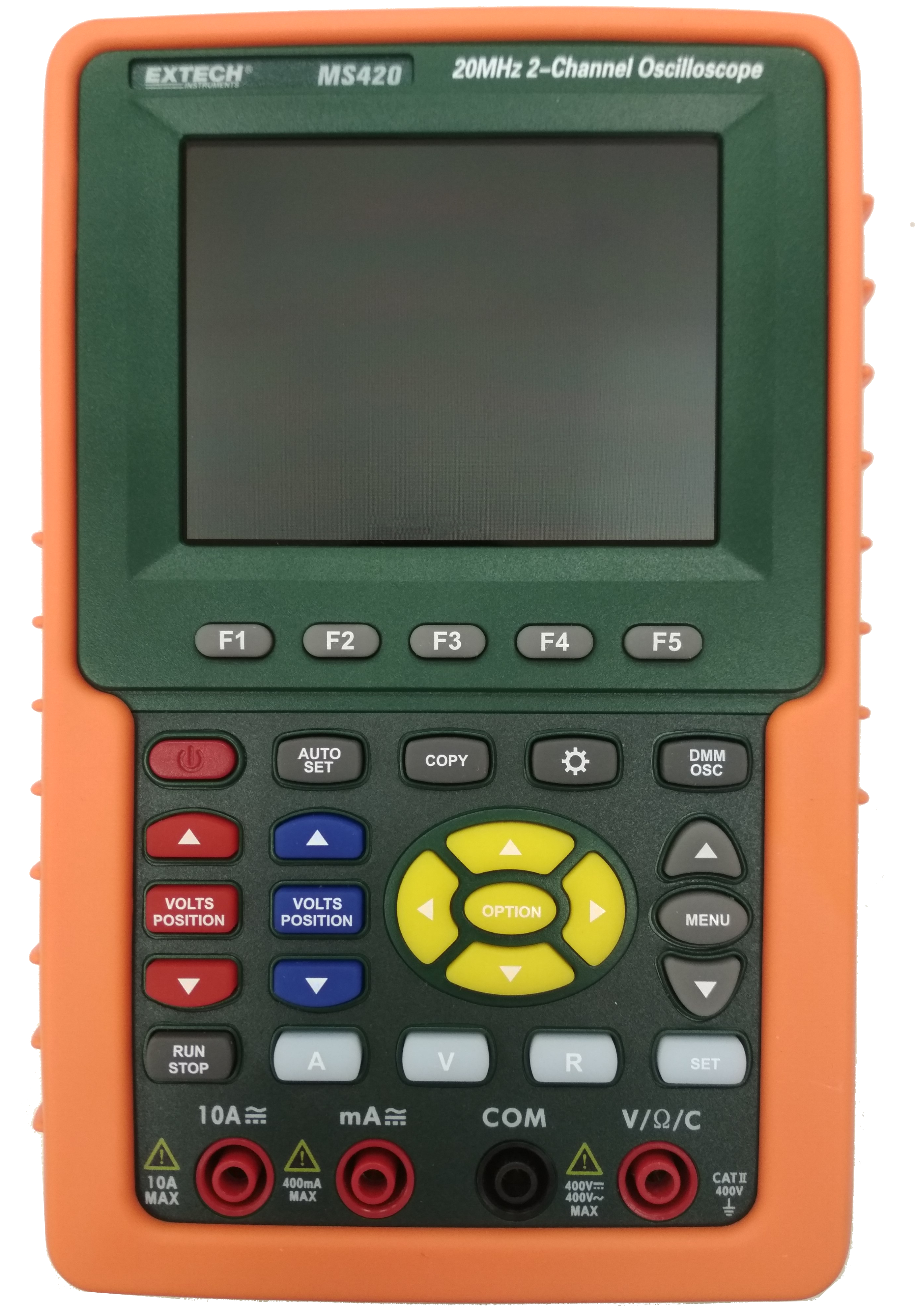

Oscilloscope (EB01A) guides students through hands-on activities using industrial-grade test equipment. Students gain essential skills in the function and operation of an oscilloscope including identifying oscilloscope controls, adjusting probe compensation, and measuring AC voltage and frequency with an oscilloscope. The skills-based curriculum presents hands-on activities using an industrial grade oscilloscope as well as electrical components mounted on two included Flexponent™ panels which attach to the JobMaster Learning Station.

88-EB01A-0000

[Ver: 3.2.2.0]

Digital Multimeter (EB01B) guides students through hands-on activities using industrial-grade test equipment. Students gain essential skills in the function and operation of a digital multimeter including safety, measuring voltage and resistance, testing grounds and more. The skills-based curriculum presents hands-on activities using an industrial grade digital multimeter as well as electrical components mounted on two included Flexponent™ panels which attach to the JobMaster Learning Station.

Cat. Number: 88-EB01B-0000

[Ver: 2.1.3.0]

Hand-held Digital Oscilloscope (EB01C) delivers hands-on skills in operating industrial-grade test equipment. Hand-held Digital Oscilloscope (EB01C) is an add-on to Oscilloscope (EB01A), covering eight additional skills including identifying oscilloscope controls, performing AC voltage calculations, and measuring frequency. The skills-based curriculum presents hands-on activities using a hand-held digital oscilloscope along with the Flexponent™ panels included with the prerequisite course Oscilloscope (EB01A). Panels are easily added and exchanged on the JobMaster™ Learning Station.

Catalog Number: 88-EB01C-0000

[Ver: 3.0.1.0]

DC Power Supplies (EB02A) delivers hands-on skills in operating industrial-grade bridge rectifiers, transformers and test equipment, including drawing power supply block diagrams, connecting and operating full-wave DC power supplies and single-phase bridge rectifiers. The skills-based curriculum builds on the concepts learned in the prerequisite test instruments courses: Oscilloscope (EB01A) and Digital Multimeter (EB01B). DC Power Supplies (EB02A) presents eleven additional skills using bridge rectifiers, diode rectifiers and low-voltage transformers mounted on three included Flexponent™ panels which attach to the JobMaster Learning Station.

Cat. Number 88-EB02A-0000

[Ver: 2.0.1.1]

Single-phase and Three-phase Power Supplies (EB02B) delivers hands-on skills in operating industrial-grade bridge rectifiers, transformers and test equipment, including connecting and operating a zener diode voltage regulator, operating a DC power supply with an IC voltage regulator, and testing a three-phase bridge rectifier. The skills-based curriculum builds on the concepts learned in the prerequisite course: DC Power Supplies (EB02A). Single-phase and Three-phase Power Supplies (EB02B) presents thirteen additional skills using three-phase bridge rectifiers and zener diodes mounted on three included Flexponent™ panels which attach to the JobMaster Learning Station.

Cat. Number 88-EB02B-0000

[Ver: 2.1.1.0]

Thyristor Electric Motor Drives (EB03) delivers hands-on skills in operating the same industrial-grade components used extensively in industrial electric motor drives. Students learn SCR control and PWM principles while acquiring skills including operating full-wave SCR DC motor drives, DIAC-controlled TRIAC AC motor drives and Schmitt Trigger-Controlled TRIAC AC Motor Drives. The skills-based curriculum builds on the concepts learned in the prerequisite Industrial Power Electronics series. Thyristor Electric Motor Drives (EB03) presents fifteen additional skills and eight additional Flexponent™ panels for use with the JobMaster Learning Station.

Cat. Number 88-EB03-0000

[Ver: 2.0.1.0]

Electronic Timers (EB04) delivers hands-on skills in operating the same industrial-grade timer devices used extensively in time-delay relays, motor drives and digital circuits. Students acquire skills including connecting and operating a 555 timer, verifying an astable timer circuit and connecting and operating an electronic pulse train. The skills-based curriculum builds on the concepts learned in the prerequisite courses: Oscilloscope (EB01A) and Digital Multimeter (EB01B). Electronic Timers (EB04) presents six additional skills with a timer Flexponent™ panel which attach to the JobMaster Learning Station.

Cat. Number 88-EB04-0000

[Ver: 2.0.1.0]

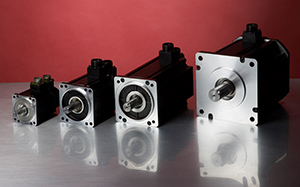

Stepper Motor Drives (EB05) delivers hands-on skills using stepper motor systems found in robots, precision linear positioning devices, CNC machines and other devices that provide motion control with calculated accuracy. Students acquire skills including confirming stepper motor step angle, installing and monitoring a basic stepper motor drive and troubleshooting stepper motor drives. The skills-based curriculum builds on the concepts learned in the prerequisite courses in the Industrial Power Electronics series. Stepper Motor Drives (EB05) presents seven additional skills with an industrial-grade stepper motor and drive mounted on a Flexponent™ panel which attaches to the JobMaster Learning Station.

Cat. Number 88-EB05-0000

[Ver: 2.0.1.0]

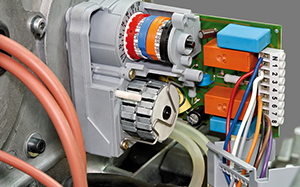

Servo Motor Drives (EB06) delivers hands-on skills using precision servo motor systems found in CNC machines, robotic and hydraulic systems. Students learn closed-loop servo motor control and system feedback principles while acquiring skills including installing, monitoring and troubleshooting servo motor drives. The skills-based curriculum builds on the concepts learned in the prerequisite courses in the Industrial Power Electronics series. Servo Motor Drives (EB06) presents six additional skills with an industrial-grade servo motor and drive mounted on a Flexponent™ panel which attaches to the JobMaster Learning Station.

Cat. Number 88-EB06-0000

[Ver: 2.0.2.0]

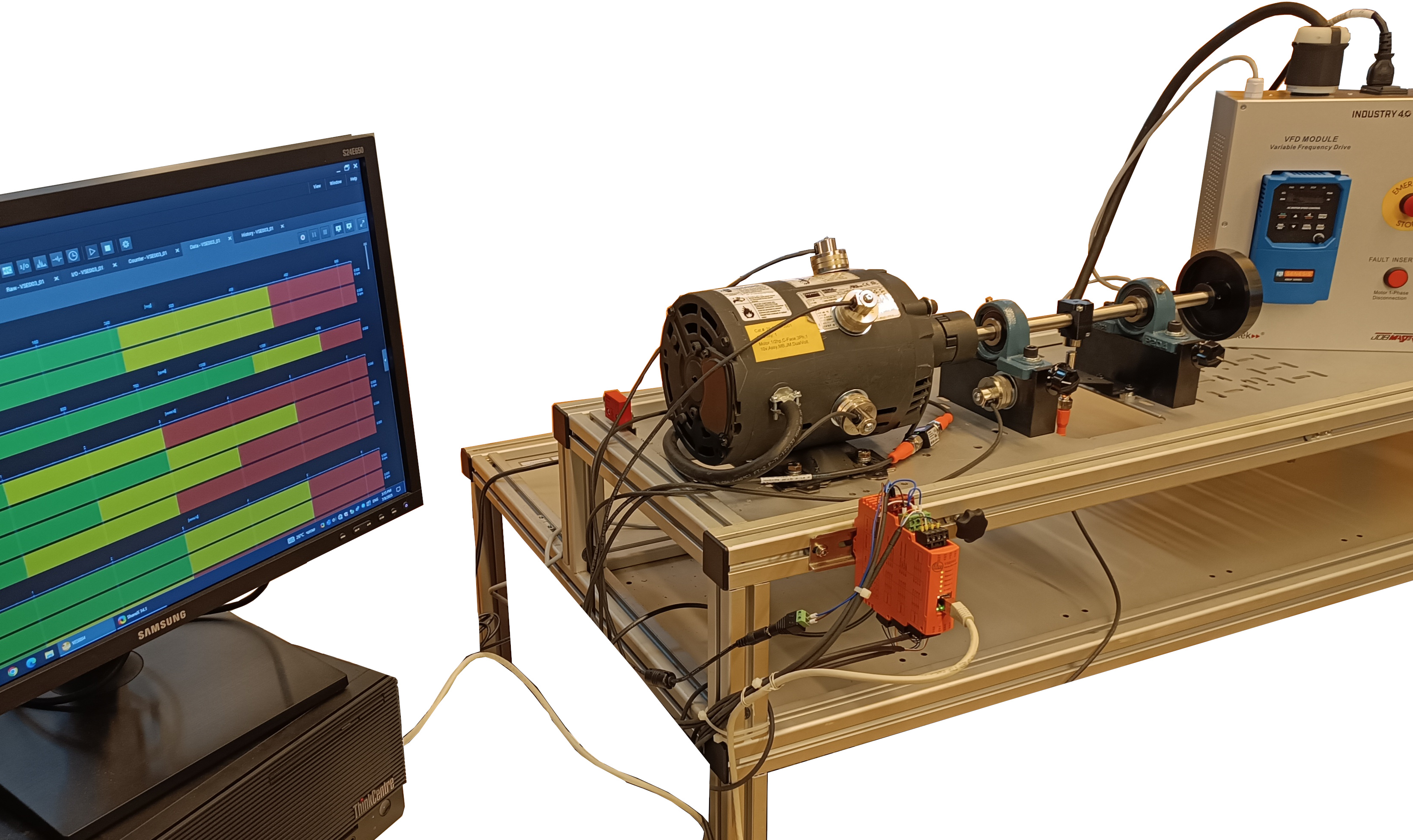

CBM for Industry 4.0 introduces students to the world of machine diagnostics and informs them on how to use state-of-the art smart sensors to monitor the conditions of machines and identify subtle defects before they become big problems. While it is an essential companion to predictive maintenance, condition-based monitoring (CBM) also concentrates on general machine health and efficiency.

Intelitek’s JobMaster Machine, a modified variant of the JobMaster Mechanical Bench, is the focus of this course. Following guided instructions, students cause minor faults in the machine and then explore how these machine defects can be identified using sensors and monitoring software.

CBM sensor kit includes a magnetic sensor for monitoring rotational speed, a temperature sensor, and four all-important vibration sensors. The vibration sensors provide the bulk of the data used by the student-analysts, who will use the tools in the monitoring software to find machine abnormalities such as unbalance, looseness, and misalignment.

Catalog number: 88-3300-0011

Version number: 1.0.0.1

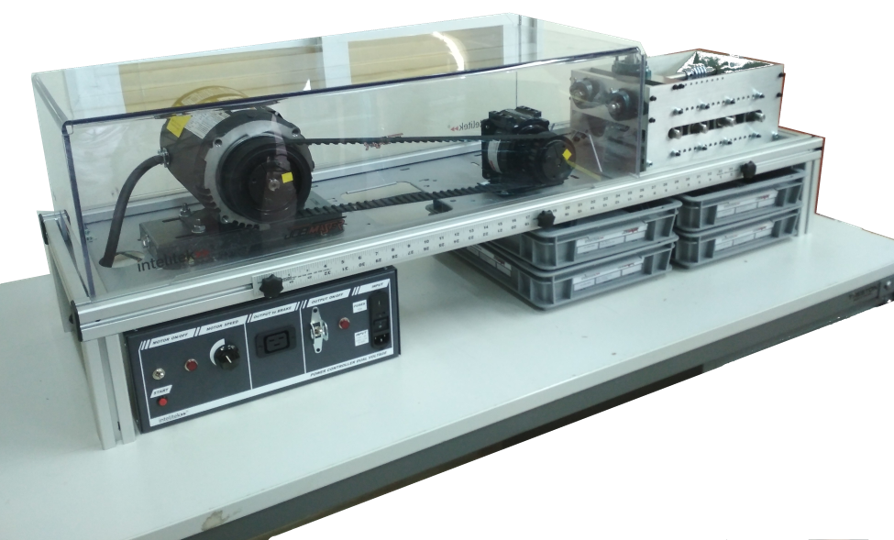

The JobMaster(r) Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through ten courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME01, basic machines are covered.

Cat. Number 88-ME01-0001

[V 3.0.3.0]

The JobMaster Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through ten courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME02, machine statics and dynamics are covered.

Cat. Number 88-ME02-0001

[V 3.0.2.0]

The JobMaster(r) Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through ten courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME03, machines shafts and keys are covered.

Catalog number 88-ME03-0001

[V 3.0.1.0]

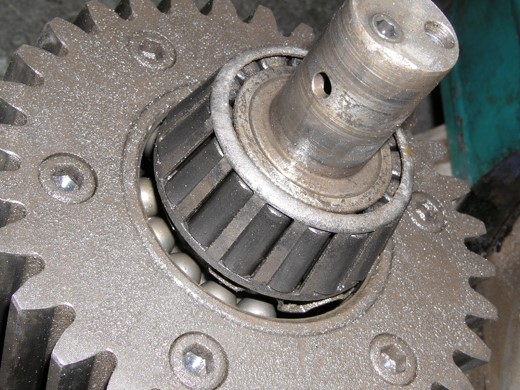

The JobMaster(r) Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through ten courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME04, bearings are covered.

Catalog number 88-ME04-0001

[V 3.0.1.0]

The JobMaster Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through ten courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME05, belt drives are covered.

Catalog number 88-ME05-0011

[v 3.0.1.0]

The JobMaster Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through ten courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME06, chain drives are covered.

Cat. Number 88-ME06-0011

[V 3.0.1.0]

The JobMaster(r) Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through ten courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME07, machine shafts and couplings are covered.

Cat. Number 88-ME07-0001

[V 3.0.1.0]

The JobMaster(r) Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through ten courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME08, gear drives are covered.

Cat. Number 88-ME08-0001

[V 3.0.1.0]

The JobMaster Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through a series of courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME09, machine speed reducers are covered.

Cat. Number 88-ME09-0001

[V 3.0.1.0]

The JobMaster Mechanical Training Bench presents the principles of power transmission using the same industrial-strength components used in factory environments. Through a series of courses covering 63 skills, students work with basic machines, machine statics and dynamics, shafts and keys, bearings, belt drives, chain drives, speed reducers, electric brakes and gear drives. In ME10, electric brakes are covered.

Catalog number 88-ME10-0001

[Ver: 3.0.1.0]

The Laser Alignment Tools (ME11) package is an optional supplement to the JobMaster Mechanical Training Bench. This option adds Laser tools for both shaft and belt alignment along with all the hardware needed to deliver comprehensive instruction in all aspects of Laser Alignment. Using Laser Alignment Tools with the JobMaster Mechanical Bench, student learn to align shafts, pulleys and couplings, and check for soft foot using the same tools used in industry.

For use with SKF Shaft Alignment Tool TKSA 31.

Catalog number 88-ME11-0001

[Ver: 5.0.1.0]

The Vibration Analysis Tools package (ME12) is an optional supplement to the JobMaster(r) Mechanical Training Bench. This option adds a digital vibration analyzer, shafts, rotors and other industrial-grade components to deliver comprehensive instruction in all aspects of vibration analysis. Using Vibration Analysis Tools with the Mechanical Bench, students learn to measure motor vibration, identify sources of vibration such as couplings, misaligned or bent shafts and unbalanced components.

Cat. Number 88-ME12-0001

[Ver: 3.0.1.0]

The Bearing Service (ME13) curriculum is a training module for installing, removing, and servicing plain and roller bearings. Bearing Service (ME13) presents the working principles of bearings in the most effective way: by using the same industrial-strength components used in factory environments. Students learn the principles of proper bearing service and work with a bearing packer, bearing pullers, an arbor press, grease gun and various bearing types.

[Catalog Number 88-ME13-0001]

[Ver: 3.0.0.0]

The Electromechanical Maintenance Cell is the ultimate capstone to any industrial maintenance / mechatronics program. Students learn to assemble, wire, maintain, and troubleshoot electromechanical systems just as if they were in the industrial environment.

[Ver: 1.2.1.0]

Introduction to Industry 4.0 offers a window into the impact of the Fourth Industrial Revolution and its accompanying technologies on the modern manufacturing industry. Using examples and analogies from real-world enterprises, the course explores Industry 4.0 concepts, processes, and technologies such as Big Data, artificial intelligence, the Internet of Things, augmented reality, and cognitive computing, and testifies to how these components interconnect together in order to grow the manufacturing industry of the future.

Catalog number: 77-3301-0010

Version number: 1.1.0.0

- Teacher: David Crowell

Introduction to the Internet of Things and Connectivity focuses on the vast network of smart sensors and devices that is the Internet of Things (IoT) and its impact on Industry 4.0 and the manufacturing world. This course also explores topics related to the interconnection of IoT and industrial devices, such as SCADA systems, cloud computing, edge computing, and machine vision systems.

Catalogue number: 77-3301-0011

Version: 1.1.1.0

- Teacher: David Crowell

Introduction to Big Data for Industry 4.0 explores the modern world of data, including its collection, processing, management, visualization, and ultimately, its use for financial gain.

This course also delves into topics that are associated with big data and its implementation in cutting-edge manufacturing, such as machine learning, predictive analytics, modeling, simulation, and improvement of processes and progress indicators.

Catalog number: 88-3301-0013

Version number: 1.1.1.0

Introduction to Networking and Cybersecurity for Industry 4.0 takes an in-depth look at the how's and why's of communication exchange in modern industry. From the origins of the Internet and modern computers to the Industrial Internet of Things (IIoT) and Cloud technologies, the first part of this course covers an abundance of Industry 4.0's key networking principles.

The second part of the course concentrates on the structure and importance of industry-focused cybersecurity. It explores the multitude of threats that manufacturing entities have to contend with and examines the techniques that these companies employ in order to combat them.

Catalog number: 77-3301-0012

Version number: 1.1.0.0

There are many new technologies that allow Industry 4.0 to take shape. Advanced Industry 4.0 Concepts explores how these technologies interact with each other and with traditional industrial components to create efficient, productive, and profitable enterprises.

With heavy emphasis on use cases, this course investigates concepts such as digital threads, flexible manufacturing, and advanced asset tracking and examines how these ideas intermingle to form a functioning smart factory.

Catalog number: 77-3301-0015

Version 1.0.1.1

Software Technologies for Industry 4.0 explores the different types of software that are essential for a production company's success in the new automated and modernized commercial and industrial landscape.

The types of software technologies covered in the course include, but are not limited to, ERP, MES, digital twinning and simulation, CAD, AI, business intelligence, augmented reality, and APS.

Catalog number: 88-3301-0018

Version: 1.1.2.0

Advanced IIoT and Connectivity for Industry 4.0 focuses on the vast network of smart sensors and devices that is the Internet of Things (IoT) and how such systems are integrated and deployed in today's industrial environments.

Building on the introductory course, Advanced IIoT and Connectivity delves deeper into the workings of industrial operation technologies (OT) and information technologies (IT).

Catalogue Number: 77-3301-0016

Version: 1.0.0.0

- Teacher: David Crowell

Advanced Cybersecurity for Industry 4.0 explores high-level cybersecurity concepts and investigates the various ways that cyber-attacks can occur - and be prevented - in industrial control systems and IIoT-related networks.

Building on the introductory course, Advanced Cybersecurity includes deep dives into key industry-relevant concepts such as cryptography, secure design, compliance monitoring, and incident response.

Catalogue number: 77-3301-0017

Version number: 1.0.0.0

The synergy of new cutting-edge technologies has provided the impetus for the Fourth Industrial Revolution and has shaped the nature of the Industry 4.0 ecosystem. In this course, you will learn how Industry 4.0 technologies enable vast improvements for manufacturing enterprises and their end consumers such as custom mass production, enhanced customer experience, real time business processes, lean maintenance, and more.

Catalog number: 77-3301-0020

v1.0.0.0

Data collection, storage, and analytics play a massive role in the modern world, and the manufacturing industry is no different. The vast amounts of data generated by production processes and the great potential involved in the shrewd use of this data create substantial economic opportunities for businesses that are brave enough to take advantage of them.

Advanced Data Science for Industry 4.0 explores how the proper use of data can help manufacturing enterprises significantly improve their bottom line.

88-3301-0019

v1.1.1.0

In Industry 4.0 for Business, the technologies of modern industry will be investigated from a commercial viewpoint. Refining business decision-making, cultivating the customer experience, and maximizing profits are all topics covered in this course.

Catalog number: 88-3301-0021

v1.0.1.1

The Fundamentals of Electronics module introduces the student to fundamental concepts of electronics. The module reviews basic concepts of electricity necessary to understand electronics, and proceeds to introduce various electronic components and their uses. In the first ten activities, this module teaches essential concepts relating to electronic circuitry, conversion of alternating current to direct current, semiconductors, and the structure and use of transistors and various diodes. The student is introduced to regulation and filtration of electrical current for use in electronic systems. In the last five activities, the student is introduced to logical and binary systems, necessary to the understanding of logic gates, which are at the heart of electronics systems. This module provides a basic understanding of the foundations of electronics systems. In this module, students are provided a basis for further study and exploration of electronics circuits and systems.

Cat. Number 88-3019-0000

[Ver: 2.0.0.0]

The Advanced Electronics module continues the sequence that was begun in Fundamentals of Electronics. In this module, students learn about integrated circuits, their structure, and various applications. Advanced Electronics explores logic gates and their uses. The module furthermore explains and illustrates flip-flops, shift registers, and counters. Finally, students explore the process of interfacing between digital electronic systems and an analog world: conversion of data from digital to analog and from analog to digital formats, acquisition of data, and displays. Students are able to gain a basic understanding of various electronics circuits and to analyze such circuits.

Cat. Number 88-3020-0000

[Ver: 2.0.0.0]

This course provides a comprehensive introduction to the operation and maintenance of semiconductor cleanrooms. It focuses on the cleanroom environment itself—its design, infrastructure, classifications, and safety protocols—rather than fabrication processes. Participants will learn about cleanroom layout, behavior and best practices, personal protective equipment (PPE), cleaning procedures, and contamination control. Additional topics include floating floor systems, hazards, particle filtration, and certification standards. By the end of the course, students will understand how to safely and effectively work within cleanroom environments across semiconductor and related industries.

Duration: 16 Hours

Part number: 88-3024-0000

[Ver: 0.1.0.0]

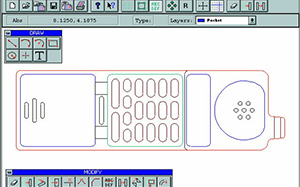

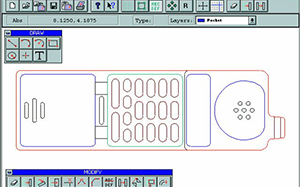

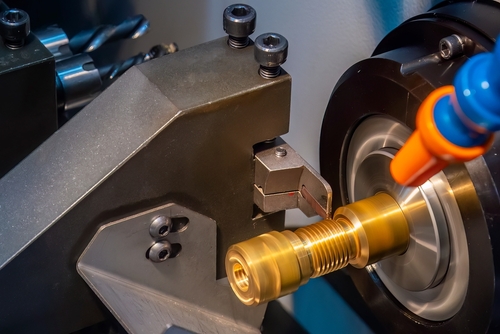

Computer-aided manufacturing (CAM) software is an important link in the manufacturing process. It forms the connection between computer-aided drafting (CAD) designs and CNC manufacturing by incorporating the machining codes within the CAD file.

The CAM Turning module introduces students to the fundamentals of CAM programs and their use in industry. The module is based on software, which converts CAD drawings into numerical control (NC) files that can be used to produce parts on a CNC turning center. The software features an integrated CAD drawing package that allows a seamless and easy working environment and includes a graphic tool path simulation package for immediate part proofing.

The activities focus on turning-related cutting operations such as roughing, facing, grooving, threading, cut-off procedures and code generation.

Cat. Number 77-3007-0002

[Ver: 2.0.1.0]

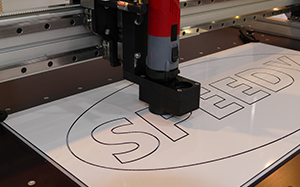

The CAM Milling with spectraCAM Milling module introduces students to the fundamentals of CAM programs and their use in industry. Computer-aided manufacturing (CAM) software forms the link between computer-aided drafting (CAD) designs and CNC manufacturing. Students are instructed in toolpath generation, contouring, engraving, pocketing, machining operations for ruled and swept surfaces, and code generation.

Cat. Number 77-3005-0002

[Ver: 2.0.0.0]

The CAD with spectraCAD Engraver module teaches you how to create and modify CAD drawings in a CAD-CAM environment. Many of the spectraCAD operations you will practice in this module will enable you to navigate features and commands that are common to most CAD software applications.

You will practice CAD commands by creating a two-dimensional drawing of an object and converting the drawing into NC code. The lessons are rich in practical instruction on industry-relevant drawing practices.

You will gain an appreciation of how CAD enables a manufacturer to design a prototype on a computer and then produce the part on a CNC (Computer Numeric Control) machine. If the prototype part fails to meet expectations, it can quickly and easily be redesigned using CAD and machined again.

Cat. Number 77-3004-0001

[Ver: 2.0.0.0]

The CAM Milling with spectraCAM Milling module introduces students to the fundamentals of CAM programs and their use in industry. Computer-aided manufacturing (CAM) software forms the link between computer-aided drafting (CAD) designs and CNC manufacturing. Students are instructed in toolpath generation, contouring, engraving, pocketing, machining operations for ruled and swept surfaces, and code generation.

77-3005-0001

[Ver: 2.0.0.0]

Computer-aided manufacturing (CAM) software is an important link in the manufacturing process. It forms the connection between computer-aided drafting (CAD) designs and CNC manufacturing by incorporating the machining codes within the CAD file.

The CAM Turning module introduces students to the fundamentals of CAM programs and their use in industry. The module is based on software, which converts CAD drawings into numerical control (NC) files that can be used to produce parts on a CNC turning center. The software features an integrated CAD drawing package that allows a seamless and easy working environment and includes a graphic tool path simulation package for immediate part proofing.

The activities focus on turning-related cutting operations such as roughing, facing, grooving, threading, cut-off procedures and code generation.

Cat. Number 77-3007-0001

[Ver: 2.0.0.0]

The CAD with spectraCAD Engraver module teaches you how to create and modify CAD drawings in a CAD-CAM environment. Many of the spectraCAD operations you will practice in this module will enable you to navigate features and commands that are common to most CAD software applications.

You will practice CAD commands by creating a two-dimensional drawing of an object and converting the drawing into NC code. The lessons are rich in practical instruction on industry-relevant drawing practices.

You will gain an appreciation of how CAD enables a manufacturer to design a prototype on a computer and then produce the part on a CNC (Computer Numeric Control) machine. If the prototype part fails to meet expectations, it can quickly and easily be redesigned using CAD and machined again.

Cat. Number 77-3004-0002

[Ver: 2.0.0.0]

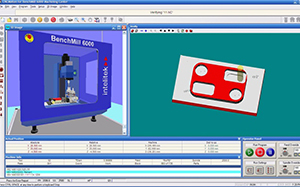

CNC Milling Technology introduces students to the fundamentals of CNC (Computer Numerical Control) milling. Students learn the fundamentals of CNC milling by working with industrial-based equipment to accurately machine a series of complex parts. Students observe and experience CNC's superiority over time-consuming, less accurate, manually controlled machine tools. Activities challenge students to develop and edit programs and machine assorted parts.

Students gain hands-on experience in proper machine set up, cutting tool selection, tool path simulation and machining center operation. Students design solutions for industrial CNC milling applications with an emphasis on real industrial concerns, such as optimized programming, accurate milling and increased productivity.

CNC Milling Technology employs CNCMotion simulation and control software and the course can be completed virtually without the use of hardware. If using hardware, the BenchMill 6000-series or ProMill 8000-series Machining Centers and their accompanying tooling kits are required.

Catalog # 88-3147-0000

v 1.2.2.1

- Teacher: David Crowell

Cat. Number 88-8160-0001

[Ver:1.2.1.1]

CNC Turning Technology introduces the student to the use of lathes. The basic concepts of CAM (Computer Aided Manufacturing) are introduced and developed. CAD (Computer Aided Drawing) functions are reviewed, enabling the student to create 2D part drawings.

The student masters the software through a series of projects. Each project teaches, with increasing complexity, job setup, drawing construction, tool path generation, tool path verification and NC code generation. The projects introduce all of the commonly used tool path parameters that can be set. Students also learn how to specify customized cutting tools.

Students create facing, roughing, finishing, drilling, grooving, parting and threading tool paths. Tool paths are verified using the Verify and Backplot animations. Student learn how to generate and save NC code.

CNC Turning Technology employs CNCMotion simulation and control software and the course can be completed virtually without the use of hardware. If using hardware, the BenchTurn 7000-series or ProTurn 9000-Series Turning Centers and their accompanying tooling kits are required.

Part number: 88-3148-0000

Version number: 1.2.0.0

- Teacher: David Crowell

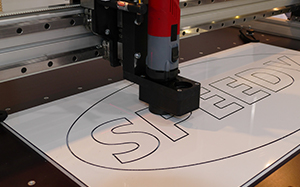

Introduction to CNC Routers with VCarve Pro is a direct, project driven course that enables students to bring objects they create to life quickly and motivates them to complete other projects. They will learn terminology related to CNC. Setting up the router using Mach3™ control software. This is followed up by five projects using Vectric VCarve Pro to produce amazing results.

Catalog number: 77-8160-0002

[v 1.0.0.0]

Introduction to 3D Printing equips students with the knowledge and skills necessary to print their own or ready-made 3D models on an FDM 3D printer. Students are introduced to the benefits of 3D printing, and the role that the Internet plays by allowing 3D models to be shared and printed around the world. Students learn how to operate typical 3D printing software. The course covers the most important printing considerations, including layer thickness, orientation, support, and in-fill. Students are also exposed to common design tools, enabling them to create and print their own models.

Cat number: 88-8157-0000

[Ver: 2.0.0.0]

This course explores the basics of 3D scanning. Students will learn about the fundamentals of the technology, as well as techniques, best practices, and tips for optimal scanning.

Catalog Number: 88-8159-0000

Version [1.0.0.0]

The Plastics Technology (Thermoforming) provides students with virtual hands-on experience combining various materials and processes to manufacture plastic parts. In this module students gain practical experience in six different plastic forming processes: Vacuum Forming, Free Dome Blowing, Plastic Welding, Plastic Dip Coating, Injection Molding and Extrusion.

Students learn how low tooling costs, short tooling lead times and great versatility make plastic thermoforming suitable for a variety of applications, such as handling trays and bins, cases and storage units, packaging and electronics housings and display panels.

Cat. Number 88-8057-0000

[Ver: 2.0.0.0]

Safety is one of the most important aspects of an industrial training program. Lockout/tagout procedures are critical in creating a safe work environment. Lockout/Tagout (LOTO) delivers skills-based curriculum through virtual and hands-on activities. Students learn all aspects of lockout/tagout procedures in industrial environments. Through interactive activities, students learn about lockout devices, conducting energy control analysis, performing lockout/tagout and more.

Catalog number: 77-LOTO-0000

[Ver: 2.1.3.0]

The Safety Fundamentals course introduces students to important safety fundamentals regarding regulations, policies, equipment, procedures, training and much more. The course starts with an overview of the regulations and policies of the Occupational Safety and Health Administration (OSHA) including employer responsibilities and employee rights. Students then learn techniques on how to make the work environment safer and how to protect themselves by using personal protective equipment. The course then provides information on handling injuries and accidents related to workers, the workplace, and equipment. After providing information on safety, the course then covers training, production team member roles, product development and customer service.

Catalog number: 88-3202-0000

[3.1.1.2]

This course explores the principles and techniques involved in Lean Manufacturing including minimizing waste in production and improving work flow in industrial processes.

Catalog number 88-3109-0000

[Ver: 2.2.2.2]

The Measurement and Quality Control module enables students to gain a solid foundation of knowledge and skill in performing measurements and calculations. In this module, the student learns to use precision measurement tools, such as steel rule, tape measure, protractor, micrometer, height gauge, various calipers and dial indicators. Students gain proficiency in reading mechanical drawings, in selecting the proper tools for inspecting parts and in preparing quality control/inspection reports.

Students learn how to collect data on a sample and calculate the mean, median and standard deviation. They also learn how these concepts relate to statistical sampling, tolerance and quality control. The module includes statistical process control activities that allows students to collect and display measurement data in a spreadsheet.

Catalog number: 88-8014-0001

[Ver 3.1.2.1]

- Teacher: David Crowell

Introduction to Advanced Manufacturing for Industry 4.0 introduces the student to the manufacturing industry and its associated career paths with an emphasis on Industry 4.0. Students learn about careers offered in manufacturing and about how to prepare for and then pursue those careers. They also explore how manufacturing companies operate. A number of common manufacturing technologies are described. The use of computers and automation in manufacturing is investigated. Students work on hands-on projects designed to provide insight into the world of manufacturing.

Catalog Number 77-3301-0014

[Ver: 2.1.0.0]

The Employability course was developed in conjunction with SkillsUSA. This course aims to prepare high school and college students with the skills required to apply for, and succeed in their first job. The course covers job application topics such as setting career goals, résumé preparation and interview skills. It provides training on basic employment skills such as time management, teamwork, communication, conflict resolution, and more. The course includes online exercises as well as offline exercises for individual and group work.

Catalog number: 88-3097-0000

[Ver: 2.2.4.2]

BA01A: Mathematics for Technicians I is designed to equip technicians with the math skills they are likely to need on a daily basis. Topics covered include arithmetic and algebra, types of numbers (whole numbers, fractions, and decimals), percentages, ratios and proportions, systems of measurement, geometry, and trigonometry.

Cat Number: 77-BA01A-0001

[Ver: 2.0.3.2]

BA01B Mathematics for Technicians 2 applies advanced mathematics concepts to everyday tasks. Through interactive activities students learn about drive ratios, Ohm's Law, mechanical principles, and how these concepts apply in the engineering and industrial environments.

Catalog number: 77-BA01B-0001

[Ver: 2.0.1.0]

BA02 Blueprint Reading delivers skills-based curriculum through virtual activities. Students learn all aspects of reading and interpreting blueprints in engineering and industrial environments, including views, tolerances, cutting planes, thread dimensions, and welding symbols.

Catalog number 77-BA02-0001

[Ver: 2.0.3.0]

- Teacher: David Crowell

BA03 Lubrication for Technicians conveys skills-based curriculum through virtual and hands-on activities. Students learn about lubrication equipment, application methods lubrication schedules, special purpose greases, synthetic lubricants, packing bearings and more.

Catalog number: 77-BA03-0001

[Ver: 2.0.1.2]

BA04 Mechanical Fasteners may be taught as a virtual course, delivered entirely online with interactive activities, or as a blended course with both virtual and hardware-based activities. Through twelve activities, students identify and work with the many types of fasteners used in engineering and industrial environments. For blended lab applications, a separate hardware package is available with all the tools covered in the activities.

Catalog number: 77-BA04-0001

[Ver: 2.0.1.0]

BA05 Hand tools play a key role in the everyday tasks of engineers, electrical technicians and other skilled professionals. Hand Tools features skills-based curriculum delivered through seventeen activities in which students learn all aspects of using hand tools. Hand Tools may be taught as a virtual course, delivered entirely online with interactive activities, or as a blended course with both virtual and hardware-based activities. For blended lab applications, a separate hardware package is available with all the tools covered in the activities.

Catalog number: 77-BA05-0001

[Ver: 2.0.3.3]

BA06 Power tools play a key role in the everyday tasks of engineers, electrical technicians and other skilled professionals. Power Tools delivers twelve skills-based activities, in which students learn all aspects of using power tools. Power Tools may be taught as a virtual course, delivered entirely online with interactive activities, or as a blended course with both virtual and hardware-based activities. For blended lab applications, a separate hardware package is available with all the tools covered in the activities.

Catalog number 77-BA06-0001

[Ver: 2.0.1.0]

The Mechanical Measurement and Quality Control module enables students to gain a solid foundation of knowledge and skill in performing measurements and calculations. In this module, the student learns to use precision measurement tools, such as steel rule, tape measure, protractor, micrometer, height gauge, various calipers and dial indicators. Students gain proficiency in reading mechanical drawings, in selecting the proper tools for inspecting parts and in preparing quality control/inspection reports.

Students learn how to collect data on a sample and calculate the mean, median and standard deviation. They also learn how these concepts relate to statistical sampling, tolerance and quality control. The module includes statistical process control activities that allows students to collect and display measurement data in a spreadsheet.

Cat. Number 88-8014-0002

[Ver: 2.2.0.0]

Advanced Foundation Skills CPT Prep Test

The Level Control module gives students hands-on experience with the measurement and control of liquid level using open loop, on/off loop and three-element (PID) control methods.

The Level Control training system serves to demonstrate and teach the measurement and control of level. The system gives students a solid understanding of the fundamentals of instrumentation and industrial process control.

Students use ProcessMotion simulation control software to practice the measurement and control of level processes using open loop, on/off loop and three-element (PID) control methods. Students raise and lower water to preset levels using manual control and auto-tuning methods. They learn how flow rate affects a preset level. Students create variable demand and supply disturbances by manipulating the panel's loading pump. Students learn to optimize the parameters for PID control of level and flow and to verify controller tuning.

Cat. Number 77-3045-0002

[Ver: 2.1.2.0]

The Temperature Process Control module enables students to study and practice the control of temperature processes using open loop, on/off loop and three-element (PID) control methods. The Temperature Process Control training system serves to demonstrate and teach the measurement and control of heat exchanger and heated tank processes. The system gives students a solid understanding of the fundamentals of instrumentation and industrial process control.

Students use ProcessMotion simulation and control software to control the virtual Process Control training panel and practice the measurement and control of two temperature processes using open loop, on/off loop and three-element (PID) control methods. Students raise and lower water temperature to preset levels using manual control and auto-tuning methods. They control the flow rate through the heat exchanger using a motorized valve, and create variable demand and supply disturbances by introducing cooled water from the reservoir tank. Students learn to optimize the parameters for PID control of temperature and to verify controller tuning.

[Ver: 2.0.0.0]

The Pressure Process Control module offers students hands-on training in the measurement and control of pressure processes using open loop, on/off loop and three-element (PID) control methods.

The Pressure Process Control training system serves to demonstrate and teach the measurement and control of pressure processes. The system gives students a solid understanding of the fundamentals of instrumentation and industrial process control.

The modules uses ProcessMotion simulation control software to control a virtual training panel for the practice the measurement and control of pressure processes using open loop, on/off loop and three-element (PID) control methods. Students raise and lower air pressure to preset levels using manual control and auto-tuning methods. Students learn how the E/P converter with the control valve affects a preset pressure in the air tank. They create variable demand and supply disturbances by manipulating the panel's valves. Students learn to optimize the parameters for PID control of pressure and to verify controller tuning.

Cat. Number 77-3044-0002

[Ver: 2.0.1.0]

The Flow Process Control module gives students hands-on experience with the measurement and control of liquid flow rates using open loop, on/off loop and three-element (PID) control methods.