CNC Milling Technology introduces students to the fundamentals of CNC (Computer Numerical Control) milling. Students learn the fundamentals of CNC milling by working with industrial-based equipment to accurately machine a series of complex parts. Students observe and experience CNC's superiority over time-consuming, less accurate, manually controlled machine tools. Activities challenge students to develop and edit programs and machine assorted parts.

Students gain hands-on experience in proper machine set up, cutting tool selection, tool path simulation and machining center operation. Students design solutions for industrial CNC milling applications with an emphasis on real industrial concerns, such as optimized programming, accurate milling and increased productivity.

CNC Milling Technology employs CNCMotion simulation and control software and the course can be completed virtually without the use of hardware. If using hardware, the BenchMill 6000-series or ProMill 8000-series Machining Centers and their accompanying tooling kits are required.

Catalog # 88-3147-0000

v 1.2.2.1

- Profesor: David Crowell

Cat. Number 88-8160-0001

[Ver:1.2.1.1]

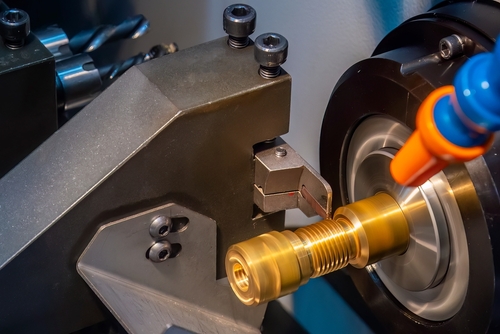

CNC Turning Technology introduces the student to the use of lathes. The basic concepts of CAM (Computer Aided Manufacturing) are introduced and developed. CAD (Computer Aided Drawing) functions are reviewed, enabling the student to create 2D part drawings.

The student masters the software through a series of projects. Each project teaches, with increasing complexity, job setup, drawing construction, tool path generation, tool path verification and NC code generation. The projects introduce all of the commonly used tool path parameters that can be set. Students also learn how to specify customized cutting tools.

Students create facing, roughing, finishing, drilling, grooving, parting and threading tool paths. Tool paths are verified using the Verify and Backplot animations. Student learn how to generate and save NC code.

CNC Turning Technology employs CNCMotion simulation and control software and the course can be completed virtually without the use of hardware. If using hardware, the BenchTurn 7000-series or ProTurn 9000-Series Turning Centers and their accompanying tooling kits are required.

Part number: 88-3148-0000

Version number: 1.2.0.0

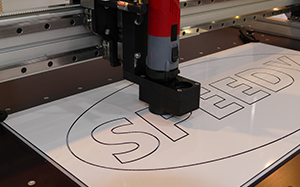

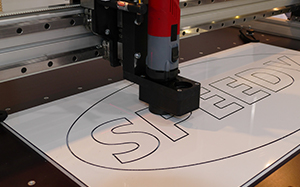

Introduction to CNC Routers with VCarve Pro is a direct, project driven course that enables students to bring objects they create to life quickly and motivates them to complete other projects. They will learn terminology related to CNC. Setting up the router using Mach3™ control software. This is followed up by five projects using Vectric VCarve Pro to produce amazing results.

Catalog number: 77-8160-0002

[v 1.0.0.0]