Fundamentals of Robotics provides students with a unique opportunity to gain experience and skill in robotic operation and programming through an industrial robotic training simulation software. This module features RoboCell, a 3D-solid modeling robotic simulation software, which allows students to expand their programming skills through a variety of simulated robotic workcells.

This module gives students the fundamental skills needed to operate, maintain, program and test robotic systems. The activities challenge students to design solutions for industrial robotic applications, with emphasis on real industrial concerns, such as recording accurate positions, optimizing programming, and increasing productivity.

In terms of robotic hardware and the YRC-series controllers, students learn how to perform skills such as manipulating the robotic arm, creating basic motion programs, resolving errors, defining coordinate systems and outlining interference areas.

Catalog #88-5005-0000

[Ver: 3.0.0.0]

- Teacher: David Crowell

- Teacher: Helena Jackson

For students who have completed the Fundamentals of Robotics module, Advanced Robotic Programming offers the opportunity to further explore robotic programming. Using RoboCell, the same 3D-solid modeling robotic simulation software that the student has previously used, Advanced Robotic Programming gives the students a greater understanding of the robotics concepts and programming commands they have already learned, as well as the ability to extend that knowledge to gain a greater understanding of robot capabilities, of working with and manipulating a robot, and accomplishing various tasks while focusing both on the goal as well as programming skills and program efficiency.

This module gives students the advanced skills needed to operate, maintain, program and test robotic systems. The activities challenge students to design solutions for industrial robotic applications, with an emphasis on real industrial concerns, such as recording accurate positions, optimizing programming and increasing productivity.

Catalog # 88-5006-0000

[Ver: 2.1.0.0]

- Teacher: David Crowell

- Teacher: Helena Jackson

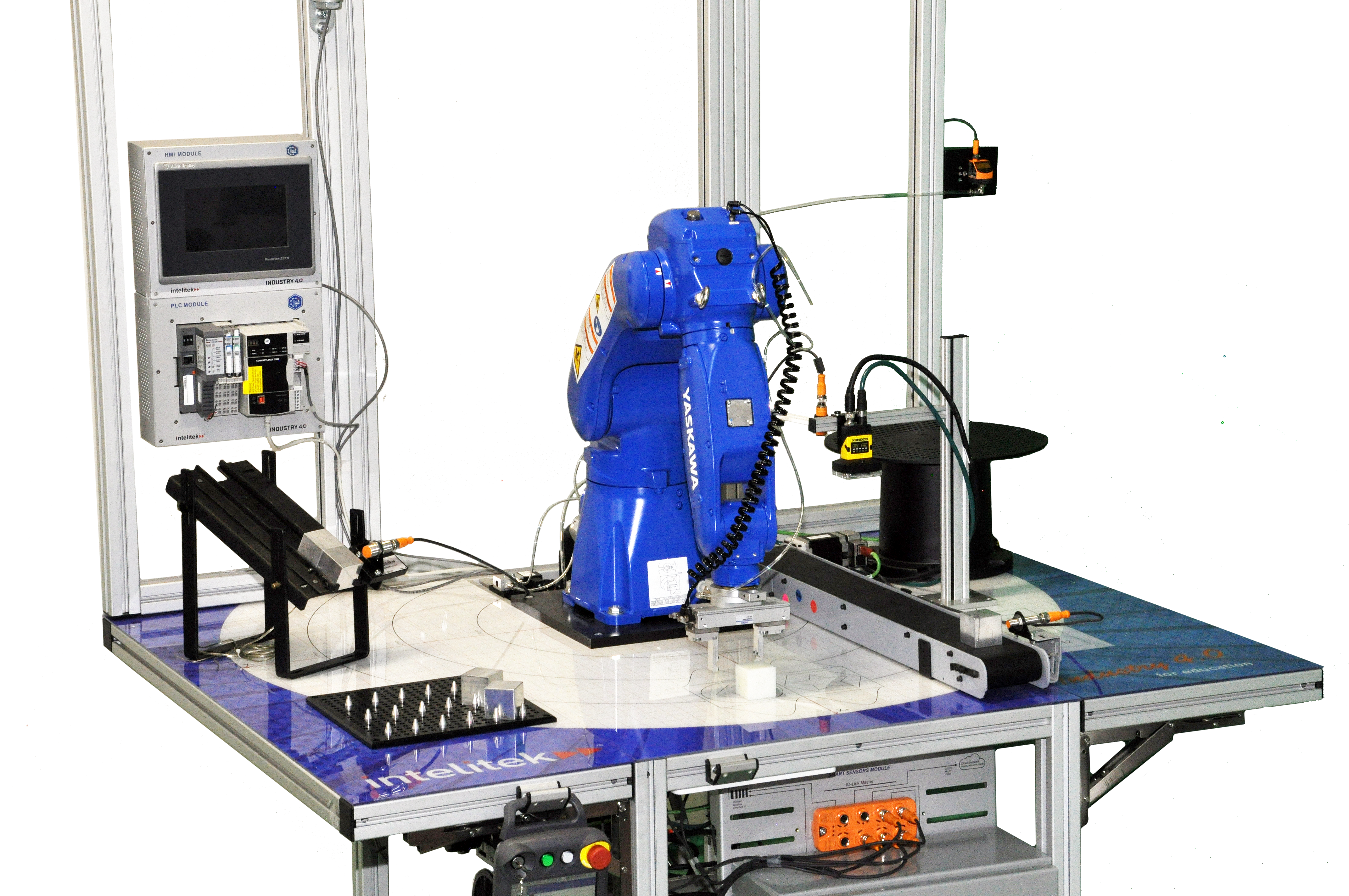

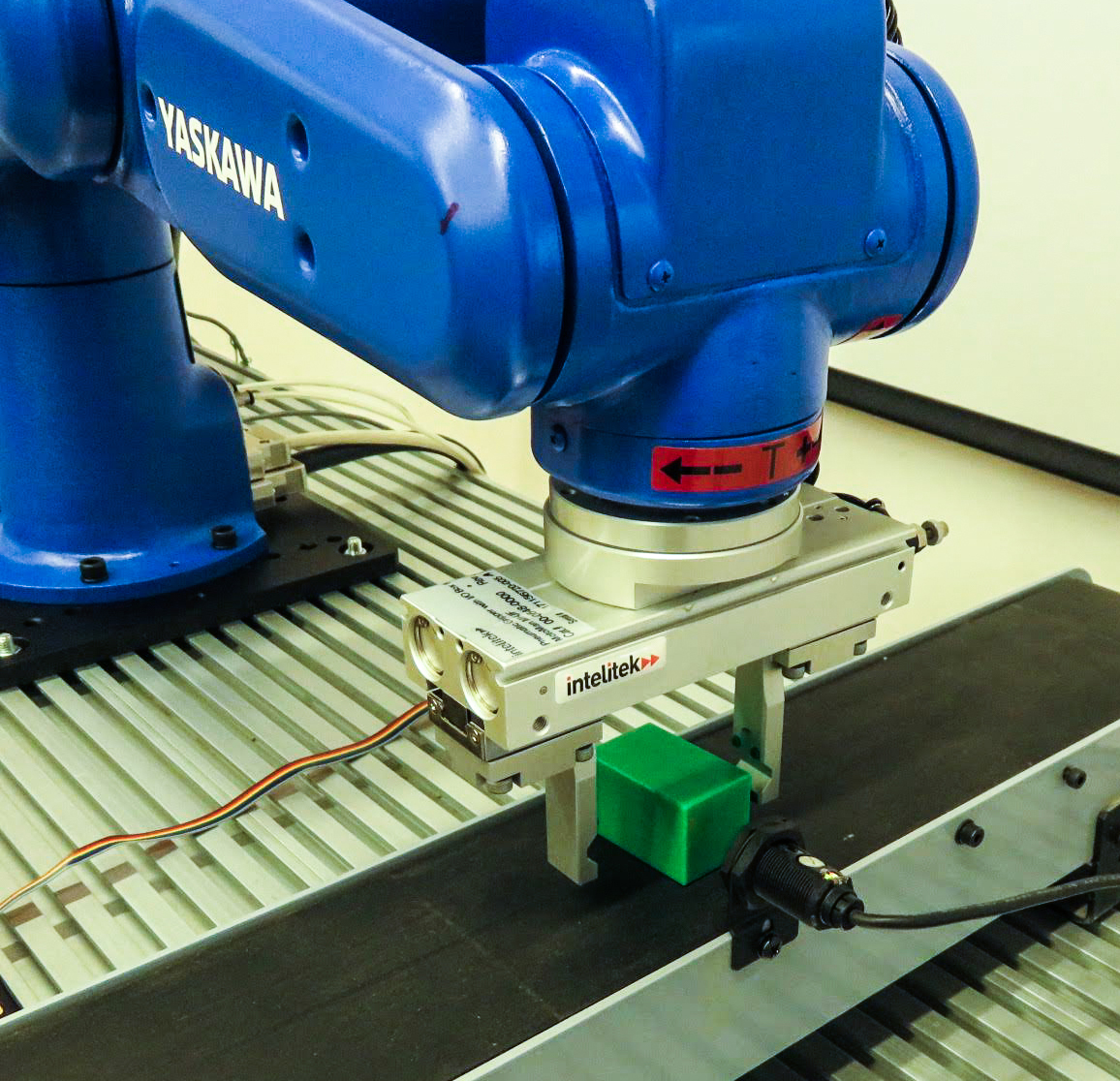

Robotics, Automation, and Integration for Industry 4.0 combines numerous modern-day concepts and branches of automation into a single course. Participants will investigate how to integrate and apply the various systems and devices in Intelitek’s SmartCart 4.0 featuring an industrial-grade 6-axis articulated robotic arm. Besides the robot, the SmartCart also includes Industry 4.0-ready automation, supervision, and inspection devices such as IO-Link smart sensors, a programmable logic controller (PLC), a human machine interface (HMI) touch screen, and a machine vision and quality control camera system.

Throughout the course, participants will learn how to perform skills such as building and maintaining an industrial network, incorporating field devices into a manufacturing environment, creating control and supervisory programs, and much more. Most of the course content is presented in the form of virtual, interactive classroom activities and hands-on laboratory tasks.

Catalog number: 88-3300-0002

Version number: 1.3.2.0

- Teacher: David Crowell

- Teacher: Aztech Resources

Catalog # 88-5007-0000

Version 1.0.0.0

- Teacher: David Crowell