Computer Integrated Manufacturing with OpenMES allows course participants to explore and operate a fully equipped industrial CIM system. With OpenMES manufacturing execution and simulation software, students can monitor system statuses, introduce customer and manufacturing orders, define processes, and optimize production.

Part 2 of this series builds upon the previous course and delves into different manufacturing concepts such as mass production, robotic systems, location planning, QC devices, part feeding, assembly, purchasing orders, MRPs, and databases.

In the course, students will learn how to design, set up and operate CIM cells that contain three to four workstations and learn about the devices used in these CIM cells and the parts that they can manufacture. In addition, students will be taught about the OpenCIM databases that play a key role in production management and storage of all the data that is collected before, during, and after production.

Course participants will also get a chance to learn about the vital aspects of a CIM production cycle, from customer order and inventory control, through automated manufacturing of materials into finished parts, to quality inspection and final delivery.

Catalog number: 88-3018-0000

[Ver: 1.0.1.0]

Computer Integrated Manufacturing with OpenMES allows course participants to explore and operate a fully equipped industrial CIM system. With OpenMES manufacturing execution and simulation software, students can monitor system statuses, introduce customer and manufacturing orders, define processes, and optimize production.

Part 1 of this course series introduces the core concepts, procedures, and stages of CIM production as well as the main components and devices in a basic CIM cell. Activities include parts and production flow, storage setup, production planning, machine definition, defining product parts and processes, timing and optimization, and integrated production.

Students will also get a chance to learn about the vital aspects of a CIM production cycle, from customer order and inventory control, through automated manufacturing of materials into finished parts, to quality inspection and final delivery.

Catalog number: 88-3017-0000

[Ver: 1.0.0.0]

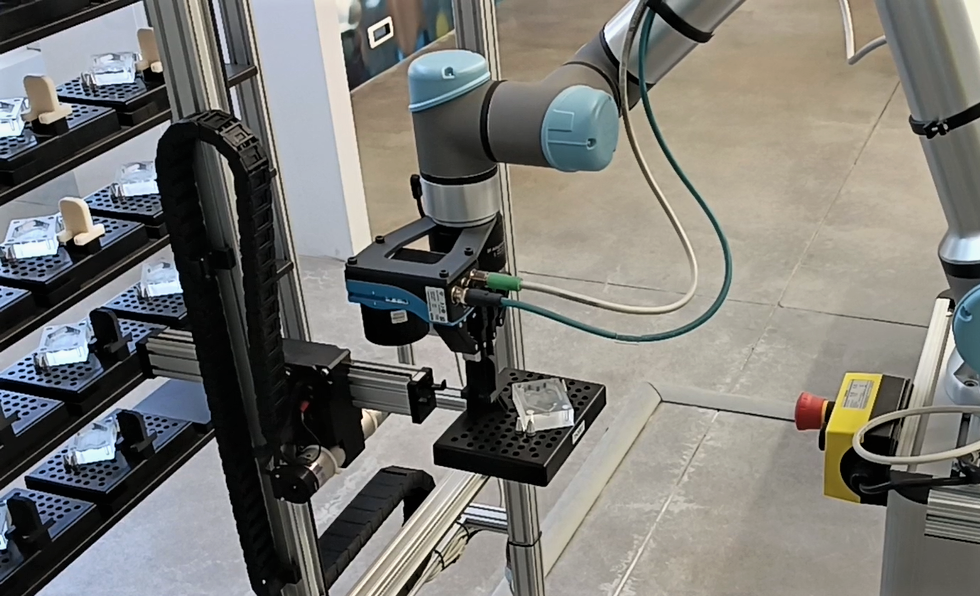

Explore the evolving landscape of the modern supply chain with the comprehensive Logistics and Warehousing for Industry 4.0.

Covering essential topics such as supply chain operations, warehouse management, and tracking technologies, this course offers a systematic approach for learning Industry 4.0 logistics.

Participants will get hands-on experience with autonomous mobile robots (AMRs), collaborative robots (cobots), automatic storage and retrieval systems (ASRS), and machine vision guidance, gaining the knowledge required to harness these technologies effectively.

The course also delves into sensor applications, safety protocols, and the role of the Internet of Things (IIoT) in smart warehousing. Students also examine how logistics software is used to optimize logistics operations.

Catalog number: 88-3301-0022

Version number: 1.0.0.0

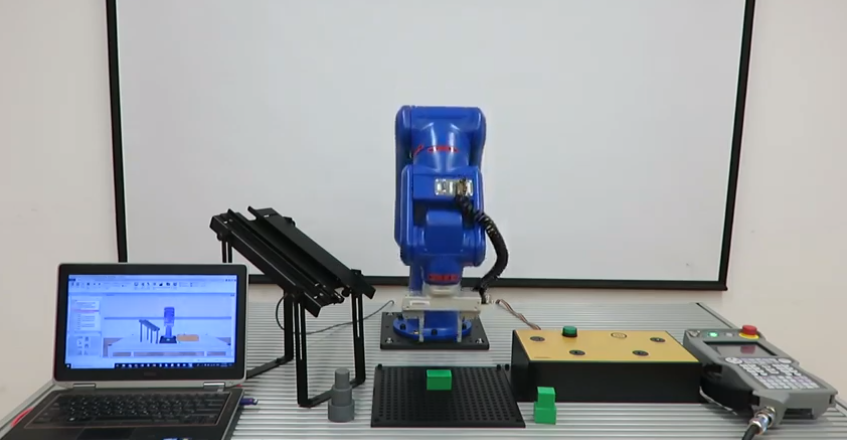

The Flexible Manufacturing System (FMS) module exposes students to automation and industrial applications by combining CNC technology with robotics and materials handling. Students develop and edit programs, record precise robotic positions, accurately mill parts, and synchronize mill and robot operation. Students gain "virtual hands-on" experience in CNC and robot programming, especially in I/O commands. Students design solutions for industrial FMS applications with emphasis on real industrial concerns, such as optimized CNC and robotic programming and accurate machine tending.

RoboCell for ER9 is the software used in this virtual-only course.

Catalog number: 77-3022-0000

[Ver: 2.1.1.0]

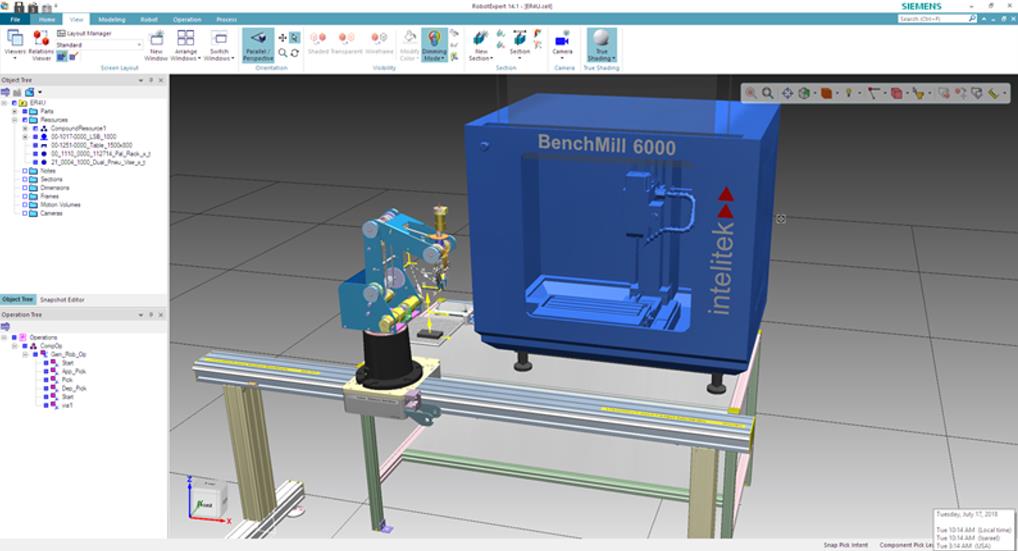

RobotExpert is a simulation and offline programming software that enables manufacturers to perform complete 3D modeling, visualization and simulation of their automation systems, including robots, tooling and peripheral equipment. In this course, we will learn the basics of how to use this full-featured program and observe how it enables manufacturers to optimize their production processes while eliminating waste and extra costs.

Catalog number: 77-8401-0001

Course version number: 1.1.0.1

Advanced Manufacturing Processes with RobotExpert is a continuation of the introductory RobotExpert Course. Siemens Tecnomatix RobotExpert is a simulation and programming software that enables manufacturers to perform complete 3D modeling, visualization, and simulation of their automation systems, including robots, tooling, and peripheral equipment. In this course, students will learn about the more advanced features of the software.

Specifically, this course delves into the following concepts:

- Collision Detection and Prevention

- Modification of Location Attributes

- Offline Programming (OLP)

- Cell Layout Optimization

- Robot Controller Selection and Setup

- Creating Robotic Programs

Catalog Number: 77-8401-0002

Version: 1.0.1.0

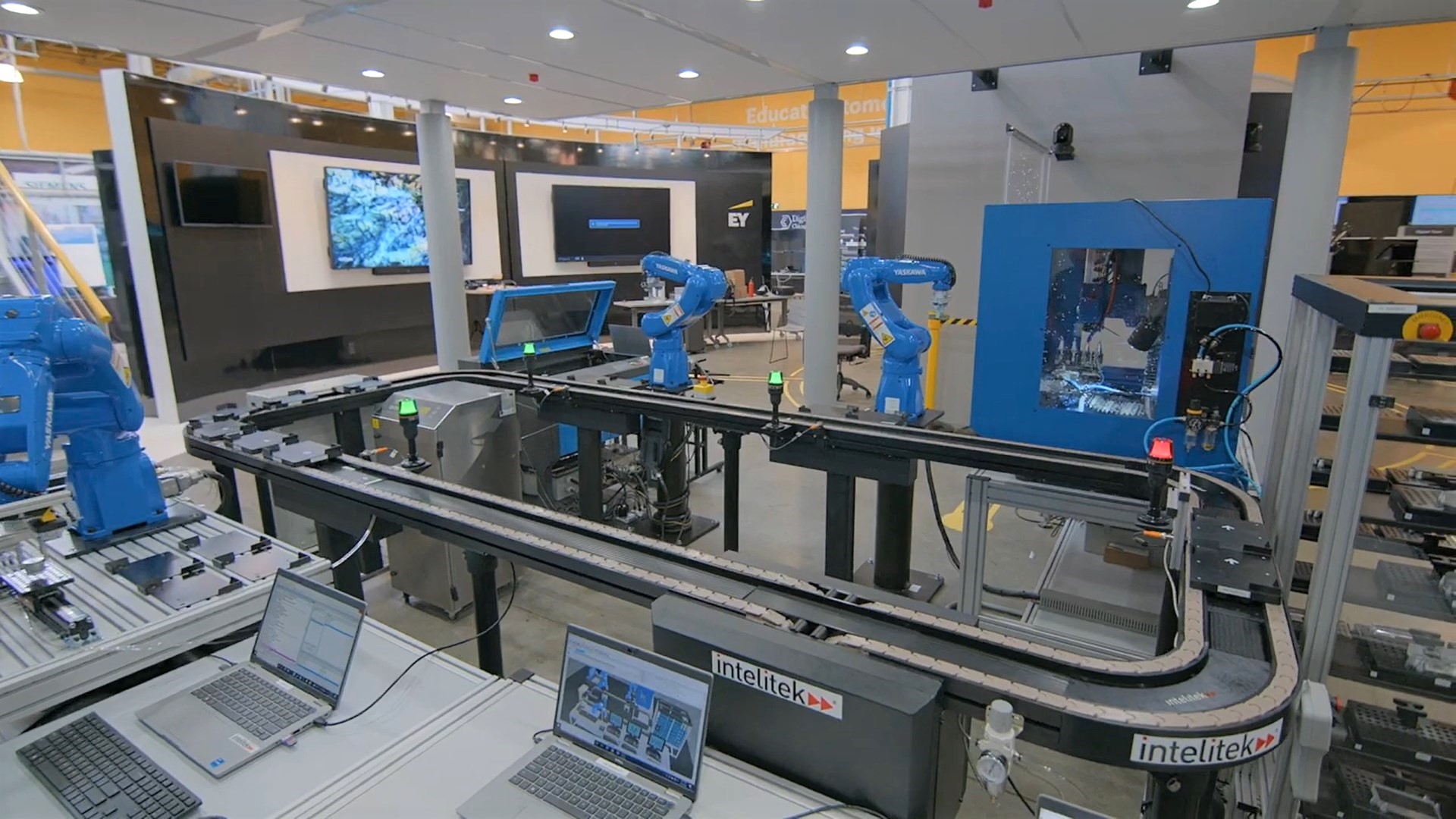

The Computer Integrated Manufacturing 1 module contains two workstations and is based on an educational system which fully replicates an industrial CIM using the OpenCIM Software. The activities in this module include parts and production flow, storage setup, production planning, machine definition, defining product parts and processes, timing and optimization and integrated production.

This module, introduces the basic concepts, procedures and key stages of CIM production as well as the main components and devices in a basic CIM cell.

Students will learn about all the aspects of a CIM production cycle, from customer order and inventory control, through automated manufacturing of materials into finished parts, to quality inspection and final delivery.

Catalog number: 88-3015-0000

[Ver: 2.0.1.1]

The Computer Integrated Manufacturing 2 module contains three to four workstations and is based on an educational system which fully replicates an industrial CIM using the OpenCIM Software.

This module assumes prior knowledge of OpenCIM software and the basic concepts and procedures that were covered in the CIM 1 module. The activities described in this module include mass production, robotic systems, location planning, QC devices, part feeding, assembly, purchasing orders, MRP and CIM databases.

In this module students will learn how to design, set up and operate CIM cells that contain three to four workstations and learn about the devices used in these CIM cells and the parts that they can manufacture. In addition, students will learn about the OpenCIM databases that play a key role in production management and storage of all the data that is collected before, during and after production.

Cat. Number: 88-3016-0000

[Ver: 2.0.2.0]