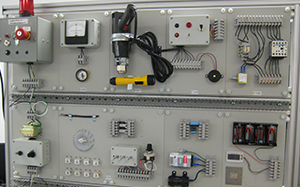

Overload/Overcurrent Protection and Monitoring (EA02) follows the four-course Basic Power Electricity series. This course guides the student through various hands-on activities regarding important safety measurements. The student learns skills such as drawing and reading circuit protection symbols, working with fuses, sizing overload heaters and circuit breakers, installing a three-phase line monitor and troubleshooting and performing preventative maintenance fuse blocks. As the students work through the curriculum, they gain experience and then demonstrate their skills to an instructor using industrial grade electrical safety components attached to the Jobmaster Learning Station.

Cat. Number 77-EA02-0000

[Ver: 2.0.1.0]

Transformers (EA03) introduces students to the various aspects of transformers. They not only learn how to apply transformer principles but also have to work through a number of hands-on activities and learn how to inspect, test, troubleshoot, disconnect, replace and reconnect transformers. Students learn how to calculate secondary voltage, primary current, primary and secondary current KVA, transformer efficiency and how to apply these calculations. The skills-based curriculum presents hands-on activities using industrial grade electrical components mounted on a three-phase power control panel (PC06) and three-phase transformer panel (E003) which attach to the Jobmaster Learning Station.

Cat. #77-EA03-0000

[Ver: 2.0.0.0]

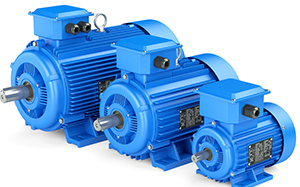

Electric Motors (EA04) guides students through hands-on activities using common industrial motors, including three-phase, split-phase and capacitor-start motors. From wiring motor circuits to preventive maintenance and troubleshooting, students gain practical experience in all aspects of industrial motor operation, including connecting and operating a three-phase motor, troubleshooting a capacitor-start motor and testing motors with adjustable loads The skills-based curriculum presents hands-on activities using industrial grade electrical components mounted on ten Flexponent™ panels which attach to the JobMaster Learning Station.

Cat. Number 88-EA04-0000

[Ver: 2.0.1.0]

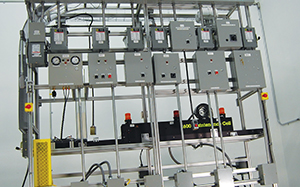

Electromagnetic Motor Starters (EA07) guides students through hands-on activities using industrial motor controls. From wiring motor control circuits to troubleshooting, students gain practical experience in all aspects of industrial motor control, including testing and resetting overload protection, operating a three-phase reversing starter and troubleshooting a three-phase motor control circuit. The skills-based curriculum presents eight critical skills using industrial magnetic starters, relays, and START-STOP motor control components mounted on six included Flexponent™ panels which attach to the JobMaster Learning Station.

Cat. Numbe 77-EA07-0000

[Ver: 2.0.0.0]

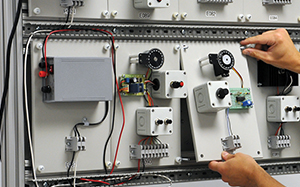

Relays, Timers & Time Delay Relays (EA08) delivers hands-on skills in installing, programming and maintaining control devices used in industrial electric circuits. Relays, Timers & Time Delay Relays (EA08) is an add-on to Electromagnetic Motor Starters (EA07), covering eight additional skills including Connecting and Programming Analog On-Delays and Off-Delay Relays, Using Digital Relays and Motors, Troubleshooting Relays. The skills-based curriculum presents hands-on activities using a digital relay and an electronic timer mounted on the two included Flexponent™ panels which attach to the JobMaster(r) Learning Station.

Cat. Number 77-EA08-0000

[Ver: 2.0.0.0]

Pilot Devices (EA09) delivers hands-on skills in installing, operating and troubleshooting pilot devices used in electric control circuits. Pilot Devices (EA09) is an add-on to Electromagnetic Motor Starters (EA07), covering ten additional skills including connecting and operating photoelectric sensors with fiber optics, capacitive and inductive proximity switches, limit switches, pressure switches, liquid level switches, and magnetic reed switches. The skills-based curriculum presents hands-on activities using industrial-grade components mounted on the four included Flexponent™ panels which attach to the JobMaster(r) Learning Station.

Cat. Number 77-EA09-0000

[Ver: 2.0.0.0]

Solid-State Starters (EA11) introduces the student to the advantages of solid state starters, why they are replacing magnetic motors in various industries and how to apply solid state starter principles. They learn the skills and gain experience in connecting, operating, testing and troubleshooting solid state starters. Throughout the curriculum the student works through various hands-on activities using industrial grade components attached to various panels such as the transformer panel (E012) and the solid state starter panel (E024) which attach to the Jobmaster Learning Station.

Cat. Number 77-EA11-0000

[Ver: 2.0.0.0]

Electronic Motor Drives (EA12) instructs students on the use of these drives through several practical activities. Students learn why the common AC motors are the drivers of industry, and will gain experience working with them. In this course they will study the principles of variable frequency drives and then learn how to connect, set up, adjust, test, operate and troubleshoot variable frequency drives. The student gains these important skills by working with an industry-standard Variable Frequency Drive and Flexponent™ panels which attaches to the JobMaster Learning Station.

Cat. Number 77-EA12-0000

[Ver: 2.1.0.0]

In DC Motor Control (EA16), students will gain practical experience by working through several hands-on activities. They will study DC drive principles and then learn how to connect, set up, operate and troubleshoot a DC drive. They will work with several Flexponent™ panels, including the DC Motor Panel (E034) which attaches to the JobMaster Learning Station.

Cat. Number 77-EA16-0000

[Ver: 2.0.0.0]